Stirling

Engines

and Plans

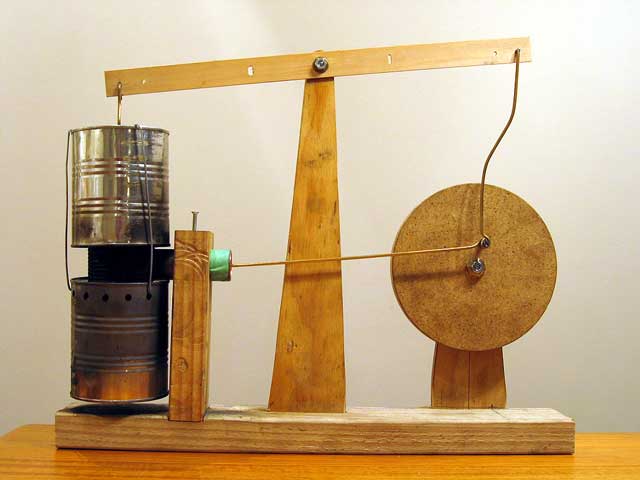

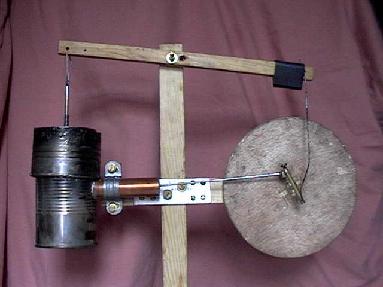

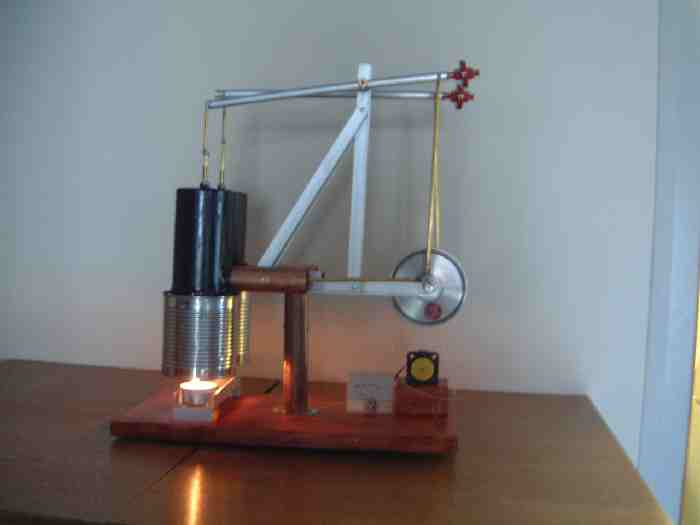

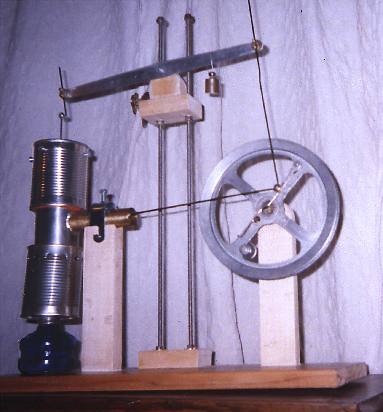

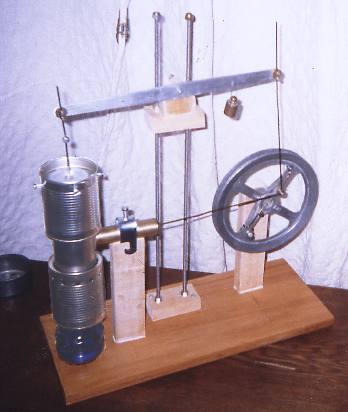

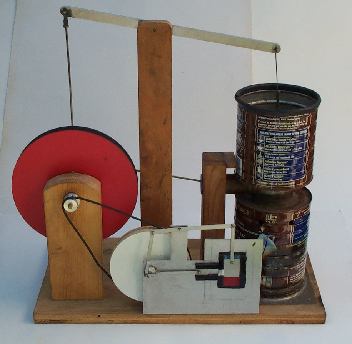

Tin can stirling engines,

walking beam stirling engines, hot air engines, stirling plans, hot air engine plans, Stirling

engine plans,

external combustion engine, Stirling plans, hot air engine plans,

Stirling

Walking Beam Engine, Sterling Engine (oops!)

Tin Can Stirling

Website

Hot

Air Stirling

Engine Web

Page

Email Me By Clicking Here

Tin Can

Stirling

Walking Beam Plans

Free!

It Really Works!!!!

Plans for building. no charge, no catch.

Really!

This site is here to help promote the

understanding of the primciples

of the Stirling engine.

It is not here to "profit" from that

information. So it is absulutly

free!

Plans, Online, Click Below

Tin Can Stirling Walking Beam

Engine Plans On Line

(New and improved images)

Plans in Word

format, click below

Tin

Can Stirling Walking Beam Engine Plans In DOC Format

158k file

Plans in PDF

format, click below"

Tin

Can Stirling Walking Beam Engine Plans In PDF Format

"How to time your engine if it is not

running correctly, click below"

Timing

your

engine

New!

Coypright Notice:

My plans are

copyrighted. If you are thinking of downloading my

copyrighted plans and selling

them on ebay (or anywhere) keep this in

mind,

I monitor ebay for such violations. I will persue the issue with

ebay and in the courts if nessesary.

I allow people to view them and use them to build a working unit

only. Not for your gain from my hard work.

Tin

Can Stirling Walking Beam

Engine Tips

and Hints

and

Changes

Includes: The new Power

Cylinder and Piston

The

Haigh piston & "Keep that displacer on!"

Oiling Tips

How to drill that brass bolt down the middle!

Stirling

Engine

Forum New!

Click Here

This forum is for all

kinds of Stirling and "Hot Air"engines,

not just the "Tin Can"engine

If you have a Stirling engine that you would like to show that

you have made from scratch (any kind),

or maybe have plans to share of it let me know. I will work with you to

make a webpage of your own.

Just email me! Email Me By Clicking Here

No copyrighted plans please (unless they are yours).

I respect the rights of others.

How

Does The Tin Can EngineWork?

This is an attempt to

explain

how this Stirling "Walking Beam" engine works.

How the

tin can displacer works

If you understand the

"displacers" function, the rest is easy.

What is going on in there?? Here's your answer

Also answers "how much clearance is between the displacer piston and

the displacer cylinder and why"

Want the entire thing!!

Here Are Two different ways to explain how

the entire engine works.

How the

Tin Can Stirling "Walking Beam" engine works #1

Partially animated (you can stop it as

you

go)

or

How the

Tin Can Stirling "Walking Beam" engine works #2

The old version

A lot of people have made

this

engine.

If you have one, please email

me and I would love a photo to use on the page

Don't

miss out on the

At bottom of page

It includes photo's of working

"Tin Can Stirling"

Also videos of them running!!

New Designs

Or Different

New!

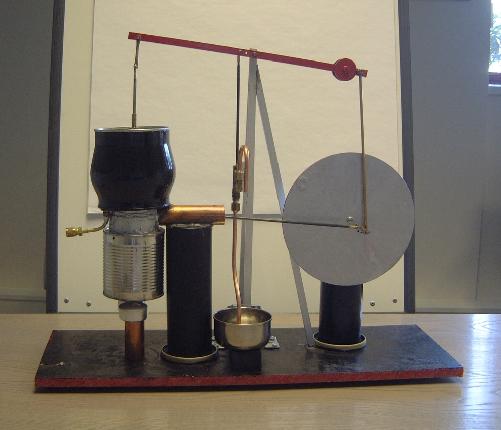

The Robertson Engine

by

Bernie Bowler

Horizontal Tin Can Engine

True horizontal tin can engine. Both

Displacer and power piston

It's taken a long time, but here it is!

Almost blew it

up!

Check it out

"How To

Build A Model

Air-Cooled

Hot-Air Engine"

Photos of

a Stirling engine built from the April 1961 Popular Science project

19 July 2005

Computerized Stirling

Engine!

Yes this engine is

assisted by a computer!

The new

"Computerized Stirling Walking Beam Engine"

News update: The "Computerized Stirling Engine"suffered catastrophic

failure on it's second run!

Gordon Harris

His Own Design

"The

Gordon Harris Stirling

Engine"

Gordon Harris

New "Two Cylinder" "Tin

Can Stirling" Engine!

" The Air Treatment Duplex Special "

Joseph Simone

A Take On The "Tin Can

Engine"

With a new type of drive called

a "Ross Yoke"

The

Ross Yoke Stirling Engine

You've got to see this drive

system work!

Brilliant!

Andi from Germany

Andi's

New Engine #2 (New Style) click here New!

Don't

miss out on the

At bottom of this page

It includes photo's of working

"Tin Can Stirling"

Also videos of them running!!

Have questions? Problems?

Email

me...Happy

to help out!!

They don't always work the first

time

out!! Most of the time they do!!

To email me click here

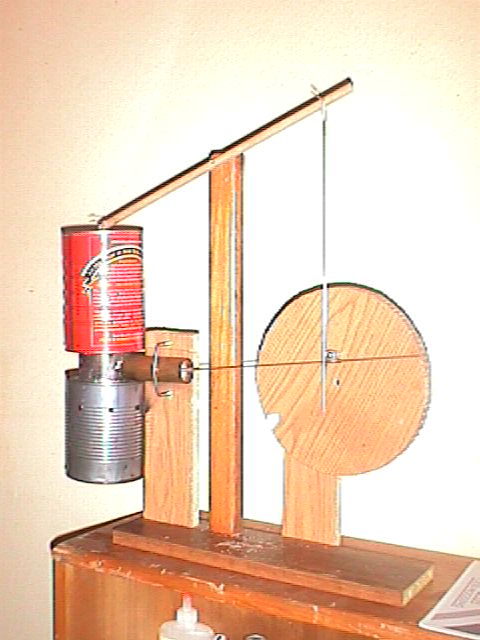

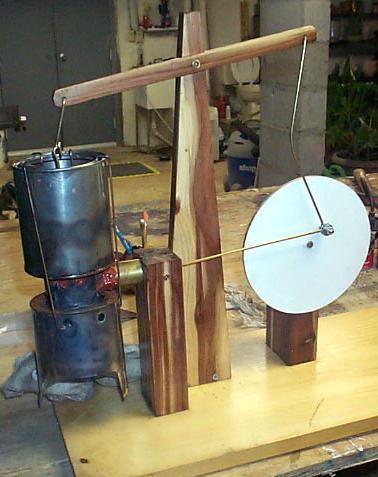

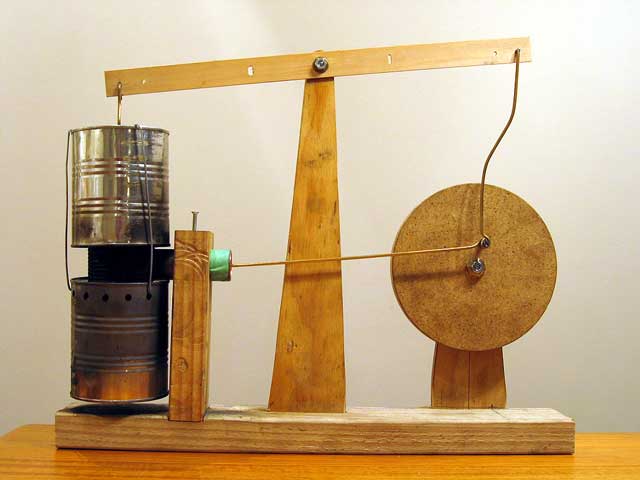

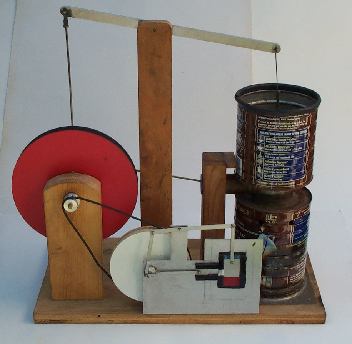

Cris LePage

Built August 2003

Martin Nobre

Built Aug 2003

Tony Gardner

Aug 03

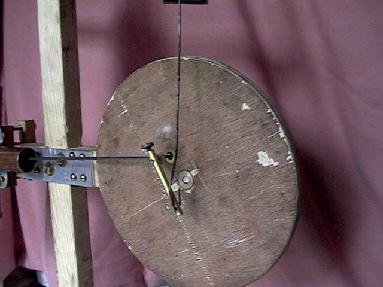

(left photo) Tony used a "VCR Video Head as

a bearing for the flywheel/crank which is nice and smooth".

William Rushing

Dec 2003

Arthur Hillier

Arthur build three different engines.

One "full sized", one "half sized", and one

"one quarter sized"

Gunnar Aske

Built Nov 2003

Piston made of epoxy!

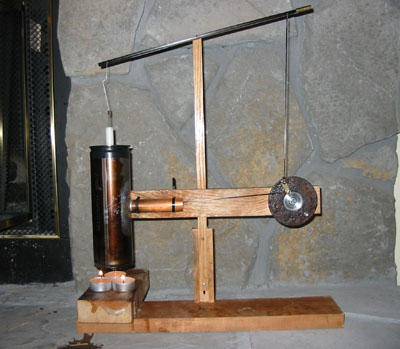

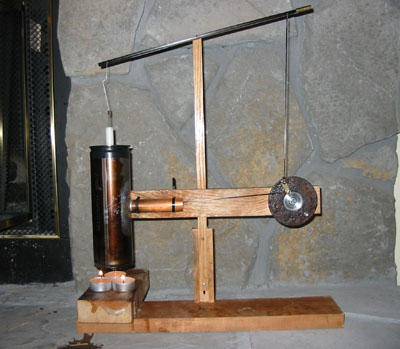

David Eaton

Somerset UK

Beam is about 6 inches long, power cylinder 1/2 inch bore.

Uses a sprit lamp!

Neil Brawley

Built May 2004

To see more of Neil's project

Click Here

Including a video of it running!

Neil Brawley's

Tin Can Engine Running!

(with sound!)

For IE users

If you're using Mozilla 1.6 or older download

and play off line or upgrade to Mozilla 1.7

Neil's

Stirling Walking Beam Engine Movie

301k WMV

file

Courtesy of Neil Brawley

Real Player Version

393k

RM file

AVI Player Version

1.8

meg AVI file

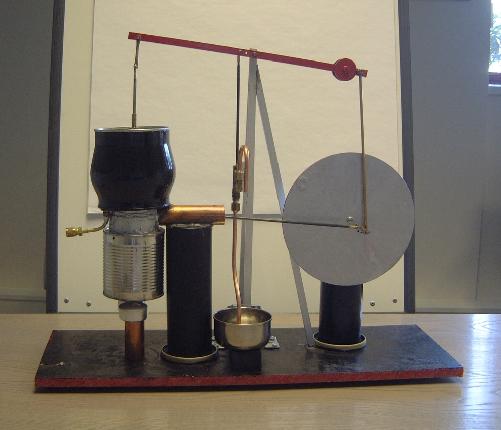

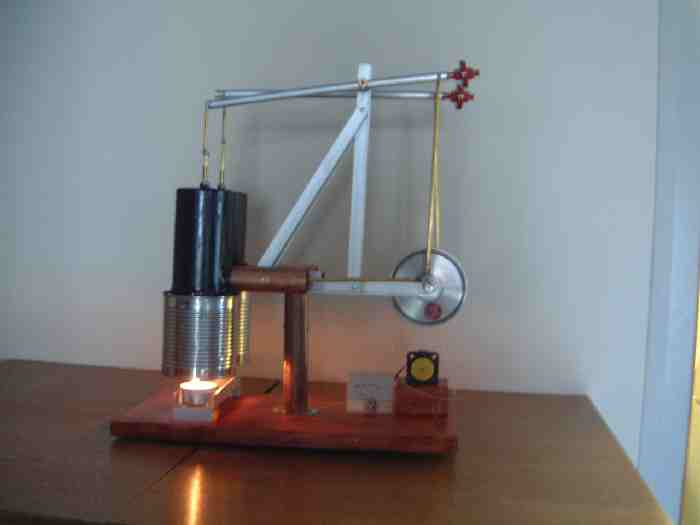

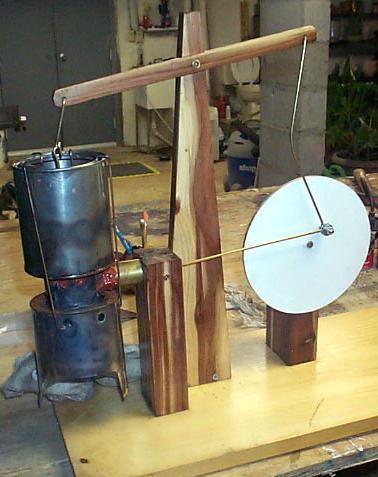

Water Pumper!!!

Gordon Harris

Built in June 2004

Gordon is an engineer in UK.

"The top half is half an aluminium filter casting with a tin can

JB welded to the bottom."

"In the UK we can get 28 mm O/D copper pipe and the piston was

the

plastic top of a

Pritt Stick ( it has three ridges that seem to work like piston

rings) which fitted perfectly and seems to

run best without lubrication."

"The engine runs very efficiently of a single night light candle,

and with two night lights does about 200 RPM."

"Because it was what they were originally used for, I fitted a

simple

piston pump.The piston and cylinder

from an old Mamod,and using bicycle ball bearings as inlet and

outlet

check valves in the fittings around

the cylinder. It pumps water fine again with only one night light

candle , but it runs faster with two."

Watch Gordon's run! (video)

Click Here

Gordon's

Stirling Walking Beam Engine Movie

1.2

meg AVI file

Check out Gordon's own design

The

Gordon Harris Stirling

Paul Wissgott

Built Summer of 2004

SE England

"-Added a balence weight to the walking beam (crank side), this

seems

to make the engine run smoother (no difference to speed).

-Added another rod to the crank area to reverse the engine rotation,

it turns clockwise as most engines turn this way.

-Heat proof super glue was used to seal transfer cylinder head,

and guide bush. (Thin Cyno 10 sec.)

-Walking beam & main crankshaft run in copper tube.Big end is

brass on mild steel pin"

"I did not do this but it may be worth experimention/ further

thought

If no lathe is avalible thick wall copper or brass tube may be the

solution to the

displacer guide bush tapped on the outside and secured with two

nuts seal with glue / solder"

"My engine will just about run on one 'nite-lite' candle but

turns

at a steady speed on two nite-lites,

solid fuel tablets or a very small butane flame."

Two Cylinger Tin Can

Engine!!

" The Air Treatment

Duplex Special "

by

Gordon Harris

Built in August 2004

Gordon is at it again!!

A two cylinder stirling tin can engine. It is driving a small

motor that is being used as a generator.

Watch his "new" video of this machine in action. Take note of the meter

the generator is hooked to!

Watch Gordon's 2nd engine running! (video)

Click Here

Gordon's

Stirling Walking Beam Engine Movie

1.8

meg AVI file

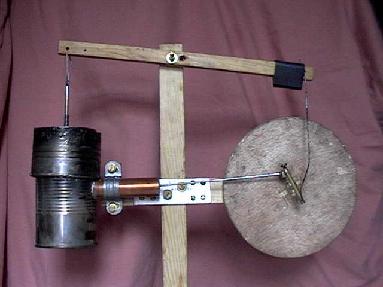

Ken Schmill

Built in January 2005

Has made two more since!

Terry Laffey

Built in January 2005

Has also made two more since!

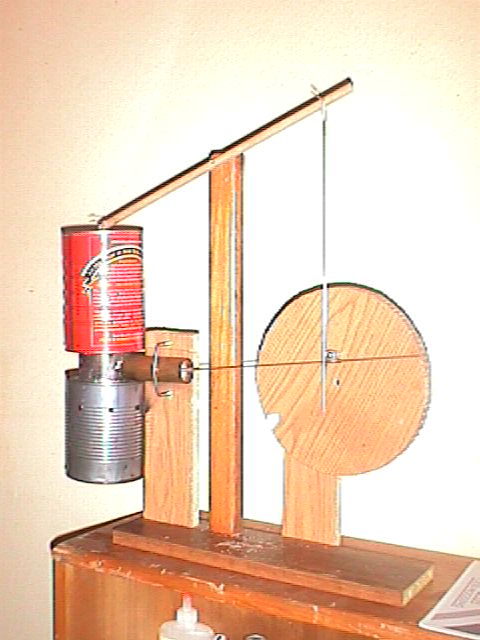

Gordon McCall

Gordon is the first one to send me a

photo of his completed Stirling engine.

He has now completed a new engine with a water pump on it. It recycles

the tank water. He is now

adding a cooling system to that pump.

Click on the photos above for a larger view.

Check this out!

Stirling

Walking Beam Pump Plans

Newest Members of the "Hall

of Flames"

Donald D. Pointer

Up and running April 2005

Also Built by

Donald

D. Pointer

Slightly different approach to the tin can engine.

Horacio Licera

Argentina

May 2005

You can

contact Horacio by email at

With last modifications runs

at 120 rpm.

Joseph Simone

150 RPM on sterno and fresh ice

water

Joe's

Stirling Engine Movie

5 meg AVI File

Darren Shabley

Completed July 2005

Ridgetown, Ontario, Canada

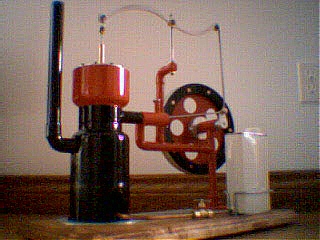

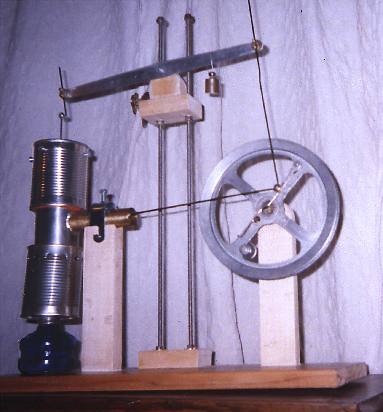

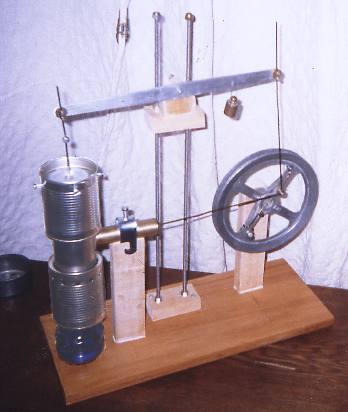

"It

is fairly large being 27" high and 21" long.(note the size of the Zippo

lighter at the base).

I am very pleased with my first attempt at a hot air engine. It runs

perfectly silent and up to approximately 180 RPM with heat coming from

a coal oil lamp.

Here are the particulars;

The displacer cylinder is made from a diesel engine oil filter.

The power cylinder and piston

were taken from an old shock absorber.

The flywheel/ crank is from a

farm tractor air cleaner

The main bearing is a valve

guide from a diesel engine with an oil hole

There are ball bearings inserted

into the connecting rod ends which I found at a hobby shop.

No machining was required, only

a welder, grinder, drill press, and a set of tap and dies.

The engine can be completely disassembled for future modifications if

required."

by Darren Shabley

|

Terry Koller

Made in 2003

Check Out Terrys Website at

terrykoller.com

Rex James

(Swan

Hill, Victoria, Australia "Down Under")

Built 2005

"The

Air Wonder"

Main points.

Displacer

piston is made from Chinese Coconut Milk Tin. This is the only tin I

could find in the supermarket that didn't have a ring pull.

However,

being a liquid, I suspect it was easier to empty out than the tomato

paste version :)

Power

cylinder is 1" outside diameter copper (Aussie specs)

Power

piston is 1" aluminium rod turned on a lathe.

Connecting

rods are all bronze welding rod.

Connecting

eyelets are all "round electrical terminals" crimped then soldered to

the rods.

Main

bearing is from VCR head as per Tony Gardner's idea on your web page.

Simple and works a treat.

Specs.

Almost

runs on a single night light candle.

64

RPM on 2 night light candles

200

RPM on spirit heater. (Old kerosene lantern preheater)

Things I

may do in the future.

Heavier

Flywheel. I suspect the light plexiglass version I have is losing some

of it's flywheel effect.

I may

hook up a pump or generator etc as it looks great when these engines

are actually doing something.

...

and of course "Build another one" :)))

|

|

Roy Shepherd

Built 2005/2006

United Kingdom

Main points.

Displacer piston is made from a

cut down bear can; displacer cylinder a bean can; fire box an treacle

can and the water tank is a sponge pudding can.

Length 48 cm; Height 36 cm.

Power cylinder is 1 cm aluminium

pipe from B&Q

Power piston is made of

Polyester Laminatins Resin.

Connecting rods are coat hanger

wire, apart from the piston rod which is copper wire.

Connecting eyelets are all male

electrical terminals crimped then soldered to the rods.

Main bearing and fly wheel is

from a floppy disk drive with a CD riveted on to it.

Specs.

Turns at 110 RPM on a homes made

spirit heater.

How to make the Power Piston.

I got a length of the 1 cm

aluminium pipe and blocked one end with a peace of wood with a tiny

hole in the centre and threaded a length of copper wire through it and

out the top of the pipe � this is used to connect the piston to the

piston rod.

Next mix the hardener with the

resin and pore it into the pipe. When the resin as gone head, ease the

piston out of the pipe and clean up the edges with glass paper. Slide

the piston through the cylinder a few times and then it will be ready

for assembly.

You can get the Polyester

Laminatins Resin and hardener from car assessory shops

Roy Shepherd UK

|

Joseph "Bill" Jackson

Built January 2006

|

I love to solder (as you can

see)and I built the basic framework out of rigid copper pipe.

Initially I had considered constructing the entire unit on a single

stalk and foot plate - but opted for the easier 2 piece construction -

one section to hold the main engine assembly and the other to hold

the fly wheel and the beam pivot. This allows for

minor adjustments in alignment.

Some aerosol cans have recessed rims ( figs.1) - the bottom

from a second can makes an ideal top for the displacer cylinder and was

easily removed with an electric can opener. I soldered a brass tube

with 1/8"ID through this top to accept the 1/8" displacer rod ( fig 2 & fig 3). After a little

careful grinding of the cylinder's upper rim, this top fit

beautifully and the recessed area provided a great mating surface for a

tight solder joint ( fig. 4).

Fig. 5 shows the

completed assembly and water jacket - notice that a slightly larger

piece of brass tubing was soldered on top of the bearing tubing and

flared to accept oil during operation of the engine ( fig. 5-a).

Figs. 6 and fig. 6-a show the front

and back of the completed engine respectively. The walking beam was cut

from 1/16" aluminum stock and the piston is epoxy (JB Weld). Although I

tried numerous other pistons , this seemed to work best. The

flywheel is a marriage of a motor flange salvaged from a defunct

vacuum cleaner and the flywheel / bronze bearing combination from

an ancient VCR (my wife has always wondered why I kept these items -

and many others - over the years - now I know - to build a

Stirling engine!) I use an alcohol chafing dish burner as a heat

source and get around 150 RPM.

My early prototypes using wooden supports and

plywood flywheel did not function well - so, my hat is off to

those who were able to get such an engine up and running. |

Additional Photos

Fig 1

Fig 2

Fig 3

Fig 4

Fig 5

Fig 5a

Fig 6

Fig 6a

Doug Simpson

Photo 1

Photo 2 Photo 3 Photo 4 Photo 5

Doug

Simpson Movie

MOV Format and 4 Megs

Terry Keathley

Built Feb 2006

Jani Pekkanen

Built May 2006

Finland

"become one nice decoration in my desk "

"Runs on a single night light candle about

65 rpm and with three candles about 195 rpm. Now it has six flame

butane burner.

Cooling is done by wet cloth.Piston is made from 20 mm plastic pipe

(used for house electric wire guide and protection).

Displacer cylinder is butane lighter refill can. Displacer piston is

crc lock oil can. Bearing is cd-rom motor."

Video of Jani's engine running from

start up!

http://tekniikka.pommi.fi/videos/Stirling_ready_low.wmv

Supa Tony

"I used the Rubber ends from the drum brake

cylinders and silicon'd them onto my main heater unit."

photo5 photo2 photo6

"This way I can pull the unit apart in seconds to EXPLAIN to

everyone how it works. (But they never really understand)."

"The piston I turned around and made a link arm from a coathanger."

photo4

"I used a Video head as my main spinner."

"I have tried to use everything from my house,

just to show people that a motor can be made easily at home."

"It really hauls when there is no water pump.

I'm averaging 210 RPM."

photo3 photo1

Donnie Barnes

Stirling engine and JB weld power piston. I

used a VCR head for the flywheel bearing, and the

walking beam and support is from some aluminum shelving I had laying

around.

I plan to install the

firebox tomorrow, but I just had to try it out this

afternoon. And it worked!!

JB Weld Piston!

Tim Oaks

Built Dec 2006

"We first used two candles to power it

but found the sterno worked better.

We have been thinking of trying a tank

from a propane torch for a displacer cylinder instead of teh paint can

so it could

stand more heat and hold up longer. It

looks like the paint can may burn out quickly being so thin."

Tim Oaks

See Tim's engine running

Click Here

MOV File 1.2 Meg

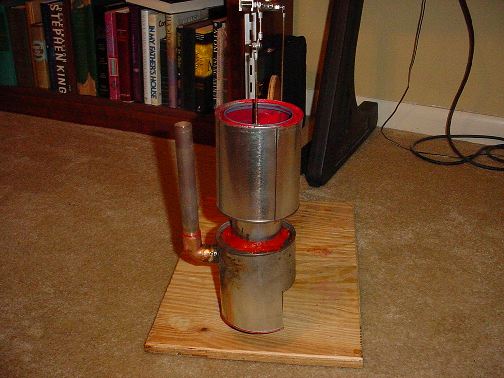

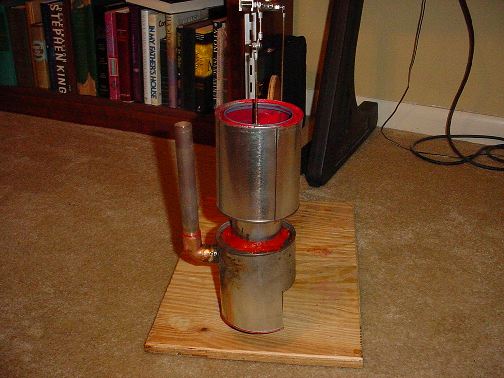

Not a "Walking Beam" tin can, but !!!

First true Vertical Tin can engine of this style

Donnie Barnes

Nov 2006

"The

displacer cylinder is an insect spray can, 7.5 x 2.5 inches and the

displacer

is a ‘Reddi Wip’ whipped

cream can 2 ¼ inches diameter, cut down to 5 inches

high. The power cylinder is ¾” id aluminum tube

with a JB Weld

piston. RPM is about 325 using Sterno fuel. I experimented

with the

timing and seem to get

the best RPM with the power cylinder adjusted to about

125 degrees before top dead center of the displacer.

I

also tried cooling fins this time. They get warm but do not seem

to hurt

the engine speed."

Donnie

Barnes

Photo 2 Photo 3

Movie of Donnies Engine running

2.9 Meg WMV file

John Dewez

" I volunteer at the San Diego California Poway

train station.

We have a Rider Stirling engine that needed to be restored so

they called me to see if I could do it.

We found out that in the 1900’s they

used the stirling to pump water to the water tower so when the steam

engine

came

around it would dump 400 gallons of water in the train. We have it

working

and run your tin can stirling just

feet away for better understanding of how it

works. My next project is to get the water pump working on the tin can

stirling.

The tin can stirling runs on propane with a 2 inch flame at the end

of a ¼ inch pipe inside a reducer from a torch."

John Dewez

Tooling/Machine

Designer

Retired

from Hewlett Packard SD

Wayne Brown

Feb 2007

Movie of engine running

AVI File

One

is 3/4 scale. My flywheels are

sidewalk scooter wheels duel ball bearing. I added weight to the pivot

to

balance the

displacer cyl. it seems to help smooth every thing out. Plus it

runs a lot longer after the heat is taken away.

Wayne Brown

Glenn Pfortmiller

Jan 2007

Photo #2

Movie of engine running

(wmv file)

Completed in Jan

2007.

The

cylinder is a brass tube about 1" diameter and the piston is corian.

The rocker arm and flywheel are also corian. The hot and cold side are

separated with a

corian base and has proven to be a good insulator. It will run

in a 70 deg F room, unlimited time,

without any cooling other than free air

cooling. It will get hot but you can still

put your hand on it without getting

burned.

Glenn Pfortmiller

Kansas

Andi from Germany

Mar 2007

I found this one

facinating enough to give Andi his own webpage. Thank

you Andi!

Andi's

page click

here

Andi's

New Engine #2 (New Style) click here New!

Oliver Cribb

Grade 7, (13 years old)

Johannesburg,

South Africa

April 2007

The bearings were taken from a

computer CD drive with a an old CD as the fly wheel weighted with nuts

around the edge stuck on with prestick.. The power cylinder is a 22mm

copper pipe and its piston made from epoxy.

Linkages are crimp lugs spaced with washers. The Displacer rod runs

through a brass bolt with an aluminium

ferrule to give a better seal. I made it in just two days during

my Easter holiday.The best speed I got from it was

about 200rpm and was very please that it ran for quite a good time even

after the heat source was removed.

Oliver's Movie

Click

Here

2 meg AVI File

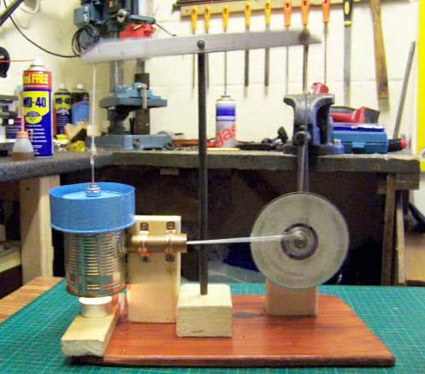

Matt Engelber

June 2007

Took the scooter wheel Idea from

Wayne's project, but used an old roller blade wheel, bearing,

and axle I got from a used sporting

goods store. I removed the bearing shields and flushed out the grease

using WD-40,

then replaced the shields. The

bearings spin very freely once the grease is out of them.

Movie of Matt's engine

Jeremy Zimmermann

Dec 2007

Jeremy is from Germany!

First for 2008

Jeff and Colin's Project

"My 8 year old son and I were looking

at your web page and were inspired to begin building an engine. We

used a 3/4" copper pipe as a cylinder, and a piece of nylon turned on a

lathe as a piston. 0.032" music wire

was used as a wrist pin. The

displacer piston is made from an aluminum V8 can, which is much lighter

than

the tin version. Piston rods are made from carbon fiber rod. The crankshaft has two 'journals' to get a

larger stroke on the displacer piston. Flywheel is made from a 1/4 inch thick

rusty steel washer mounted to a hard

drive hub which has nice bearings. The height of the base is adjustable for

different height power sources.

It has been running for several hours

straight on 2 tea lite candles. No cooling jacket yet, as we are waiting

for mom to make us pumpkin pie. The pumpkin can looks to be just the

right size."

Go

Mom!

Nice job guy's!

AVI Movie of Jeff and Colin's Engine

Running

Click

Here

1.7 Meg

Tom Burns

built March 2008

After visiting your tin can stirling Engine web-site , I just had to

get out into the workshop and have a go.

I used a bean tin and a small tomato tin for the displacer, the

information on your [ site] was very helpfull, the engine runs

well on two candles.

I was a Engineer [retired] and will pass many a happy hour making tin

can Engines. - Tom Burns.

Tom's Movie

Click Here

15 Meg MOV

Doug_Mahaney

built in April of 2008

See Doug's website on this engine at

http://www.stickmanstudios.us/stirling/

with movies, and he generates some electricity with it!

No name was sent in with this one...Sorry

Built in April or May of 2008

"She started with some plans from

another site and modified based on some of

what we saw on your site.

She won several science fair awards. Here is a

link to the youtube video if you

might want to link it into your site.

The piston is your design, the

displacer cylinder is a design mix and we used coat hangers for the

connecting rods and old CD's for the flywheel.

We found that at first it would

not turn until we added at counter weight to the displacer on the

beam. "Fat kid on the see-saw hypothesis". We got about 67

RPM on the stove. It would turn a couple times when hit with the

solar beam. The angle of the heat beam from the solar collector

did not strike the bottom of the can squarely enough to get the engine

going enough.

I think we might need to try a

horizontal version or a rotary version in order to get the solar power

to really give some RPM."

UTube Video

http://www.youtube.com/watch?v=3iHmoW2zRJY

by Dr. Dinesh Anvekar, Bangalore India

Built June 2008

Innvative features:-

* Cardboard fly wheel

* Epoxy (M-seal) power piston

* Displacer cylinder made with two copper cups joined at open ends

* Gasket material and silicone sealent used for all joints

* Epoxy (M-seal) used for water-proofing and other joints

* Coke can displacer

* Bicycle spokes and flexible wire used for linkages

* Aluminium tube power cylinder

* Cycle tube brass neck and valve pin used for displacer cylinder

opening

* PC disk drive motor used for flywheel bearing

* All wooden parts are 1.5 " or 1 " teak wood battens

* Heat source is laboratory spirit lamp

Running speed: 120 rpm

Movie of above engine

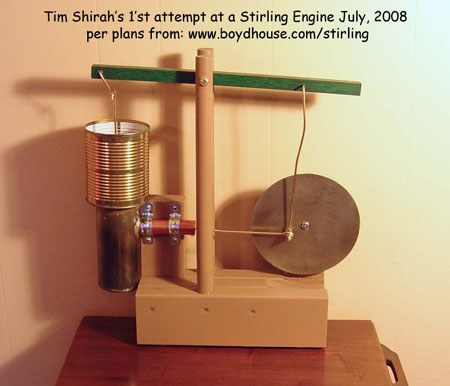

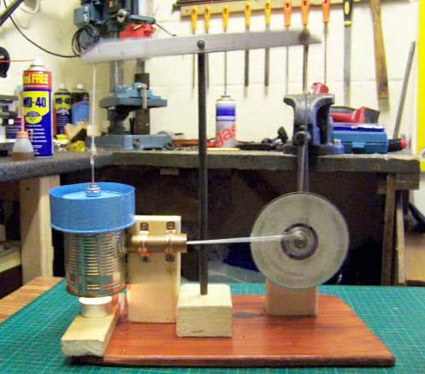

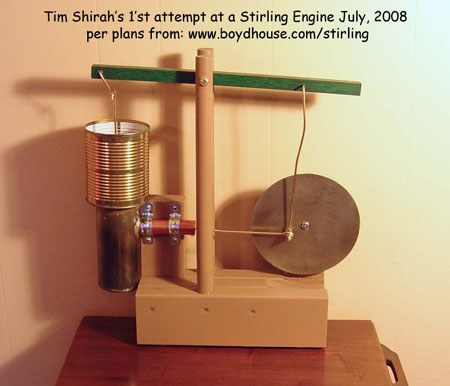

Tim Shirah

built July, 2008

I

used a can of carpet cleaner for the displacer cylinder. I had to use a

Dremel tool to remove the top since a can opener would not fit the

curved shape – it seems a spray paint can would have the same problem.

The small condensed milk can I used as a displacer piston is really a

little too tight. It sometimes touches the inside of the cylinder as it

moves up and down. The door bearing I used to mount my saw blade

flywheel has too much play, causing a slight wobble. I have not done

enough to keep the heat insulated from the drive cylinder. Even when

the engine runs at its best (around 115 rpm), it stops after 2 to 3

minutes and the epoxy piston binds in the copper cylinder. I found that

JB Weld epoxy is easier to use to mount the cooling can (I used a can

of yams) than solder, as this section never exceeds 600 deg F, the

working limit of the epoxy. The copper coupling pipe I used for my

drive cylinder is used to connect 3/4” copper pipe and is therefore

bigger in diameter. It also has a slightly thicker wall than the pipe

it joins (for strength of the coupling). I bought a 12” length to cut

down for the cylinder. A shorter coupling was used to cast the epoxy

piston.

|

Additional photos (please click on the photos for a larger view of the

photo)

Video Of Engine (youtube)

http://www.youtube.com/watch?v=Vca4lY-Wk4M

Dominic Eppolite

Dominic is possibly the oldest person to build one of

these engines.

A

note from Guy Borghi, one of Dominic's friends,

"I thought that you would be

interested in knowing that there are enthusiasts of all ages that have

built

and ran the Boyd Tin Can Stirling Hot Air Engine. My friend

Dominic

Eppolite built 3 or 4 of these engines. I have two of them which

you can

see photos of in the attachments. The unique thing about these engines

is that

Dominic built them at the age of 92. I don't think there are too

many guys

out there that have the ability to put together and operate one of

these

machines at that age. Dominic "went to be with the Lord" in May

of this year, shortly after he was diagnosed with Leukemia. He

was a

resident of the Quarryville Presbyterian Retirement Community which is

located

in Quarryville, PA.

Dominic loved to build things and many of them were his own inventions.

Just

this past March 2nd, 2009, the Lancaster Intelligencer Journal

published an

article about Dominic's life. I also included a photo of the

article

clipping in one of the attachments, where he is shown standing by a

lighthouse

he built. The article makes reference to several of the projects

Dominic

constructed and/or invented.

|

These are works of art!

A

92

year old man who shared in the enthusiasm created from building the Tin

Can Engine.

Dominic Eppolite (at the age of 92) Built February

2009.

Read story about Dominic Click Here

Rob Kay

built Aug 2009

New Zealand

|

I

used a brake piston (green

anodised!) that fitted beautifully inside the 25mm copper tube. I used

a tennis

ball can for the displacer and a small baked bean can for the displacer

piston

- it was hard to get the beans out! After the first few runs I used a

small

bearing race for the flywheel and the improvement was great. As you can

see I

used penny washers for the pivots of the rods as I found it quite

difficult to

form the end of the rods to a good shape. I did just flatten and drill

a

couple. I initially soldered legs on to the firebox but the solder

melted so I

riveted some on. I run the engine on methylated spirits (denatured

methyl

alcohol) as Sterno is not readily available here.

Rob

Kay

Nelson,

New Zealand

|

Rob Kay

built Aug 2009

New Zealand

|

I used a

brake piston (green

anodised!) that fitted beautifully inside the 25mm copper tube. I used

a tennis

ball can for the displacer and a small baked bean can for the displacer

piston

- it was hard to get the beans out!

After the first few runs I used a small

bearing race for the flywheel and the improvement was great. As you can

see I

used penny washers for the pivots of the rods as I found it quite

difficult to

form the end of the rods to a good shape. I did just flatten and drill

a

couple. I initially soldered legs on to the firebox but the solder

melted so I

riveted some on.

I run the

engine on methylated spirits (denatured methyl

alcohol) as Sterno is not readily available here.

Rob Kay

|

Dale Hoerner

Built Dec 2009

Well, I just had to send you a photo.

The

darn thing runs.

The power piston is epoxy. The fire box is a spaghetti

sauce can. All the con rods are 3/32 brass rod. The main

bearing is

a sleeve and rod from an old DVD drive (not the motor).

With one tea

candle it runs at about 60 - 75 RPM depending on how well adjusted

everything

is. I have a little too much friction in the power piston and in

the

displacer sleeve. But it sure was exciting when it ran the first

time!

Dale Hoerner

|

Morteza &

Mohamad Salimi

Built September 2009

Jan From Denmark

A few Links (Movies and Photos)

http://s280.photobucket.com/albums/kk189/speedless/Stirling/?action=view¤t=PICT0035.mp4

http://s280.photobucket.com/albums/kk189/speedless/Stirling/?action=view¤t=PICT0027.mp4

http://s280.photobucket.com/albums/kk189/speedless/Stirling/

Keithe Campbell

built 2010

|

cylinder- copper, honed

power piston -made on lathe,.002 under

cylinder

bearings - from old VHS player

push rods- bicycle spokes

wrist pin- from VHS player

heat source- can of sterno at bottom

water in top can,

displacer piston - made from balsa .

|

timing

adjustments - servo arms from RC

equipment

Mike Mathrole

Built 2008

I stayed

pretty close to the plans but I cheated

a bit and used my metal lathe to make the piston. I also used ball

bearings on

the main pivot for the walking beam, the wheel and the rod connection

on the

wheel, the other pivots on the walking beam are brass bushed for smooth

operation.

|

Our "Newest" Additions!

Tony Cunningham

|

I built this engine sticking strictly to

your design

criteria except for the following points:-

1. The top of the displacer cylinder is

not soldered on.

I have used a rubber seal instead. This allows access to the displacer.

2. I have also used a rubber "O" ring

seal

between the water jacket container and the displacer cylinder.

The water jacket container is smaller

than your original

design, only because a larger paint can was not at hand at the time.

Running

time is restricted, confirming your design criteria. I have inserted

folded

aluminium strips to dissipate some heat.

3. A picture is attached and any other

differences are

purely aesthetic.

It runs very well, easily achieving

100-150 rpm with a

small spirit burner. I lack movie making skills but I have managed to

put a

short video on youtube, should you be interested in seeing one example

of your

work. This can be found here : http://www.youtube.com/watch?v=fYsOzo-VhjM

|

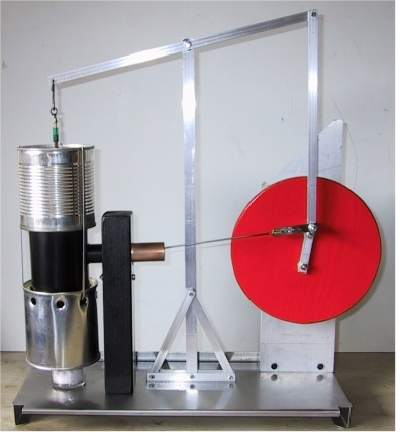

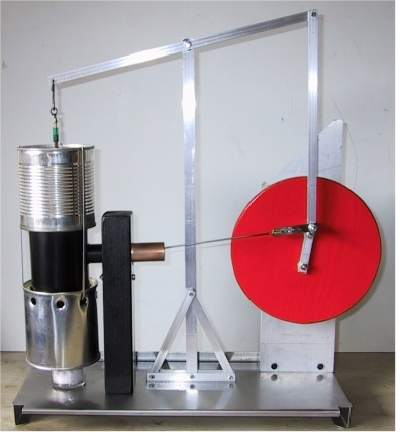

John Gardiner

built early 2011

Had scrap

aluminum

angle lying around. I love working with it... so made the structure

from it.

Made all the linkages to your exact dimensions from 1/8 welding

rod, except for

the small 1 1/2 inch link (joining the walking beam to the displacer

rod). This, I made from some scrap aluminum I had on hand.

I drilled

several

adjustment holes in it, then used a small bolt to connect to the beam.

However I added a REGENERATOR which improved performance significantly.

Here is

what I did.

The displacer was made from a a PVC metal dope can...easy to find in

Home

Depot. I cut the protruding top off and soldered on a new tin can top.

Next I got aluminum window screening 3' x 7' roll. I did not remove it from its

plastic packaging film.... but rolled the film back

only about 4" from one end.... measured the displacer length...taped

the

screen either side of my intended cut and cut it (with a cut off wheel

in a

4" Makita grinder). Then I wound it round the periphery (outside

surface)

of the displacer...had to cut maybe 2 turns off to allow it to go

through

lip...sealed the free edge with JB, taped it til it set, then secured

it with

wire, top and bottom, to displacer rod and away it went.

Improved performance immensely!!!!!! |

Rob Johnson

built Summer 2011

|

Continues

to run

sweetly...and have turned on a few friends who are also

"building"....

What I've

done that

works incredibly well is to use what's called piano wire (very very

small

diameter steel rods available at hobby shops for about 25 cents for a

three foot

length) instead of the 1/8 inch stuff.

Then instead of the bolt, I've

drilled a 3/8 inch hole in my top and shoved a black rubber stopper

(available

at the hardware store for about forty cents) up from the inside.

Once in,

it forms a perfect seal and is almost unremovable. a tiny hole

drilled in

it for the piano wire and a touch of 3 in one oil and it's virtually

frictionless and completely air tight.

My JB weld piston is a great fit

(after quite a while of very careful gentle sanding). Next time I

would

prefer the aluminum rod thing though...

|

Way cool looking Walking Beam Stirling Engine!

Bob Hammell

Built in Summer of 2011

Dan Pickard

Built in Summer of 2011

Vikram Vicky

From India

Built in Summer of 2011

A lot

of people have made

this

engine.

If you have one, please email

me and I would love a photo to use on the page

Variation

on a theme!

Not "Tin Can Walking Beam" Engines

But still "Master Pieces"

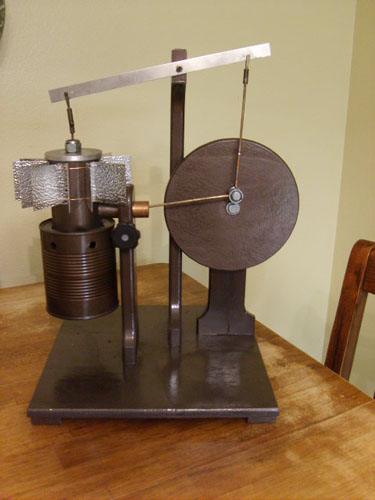

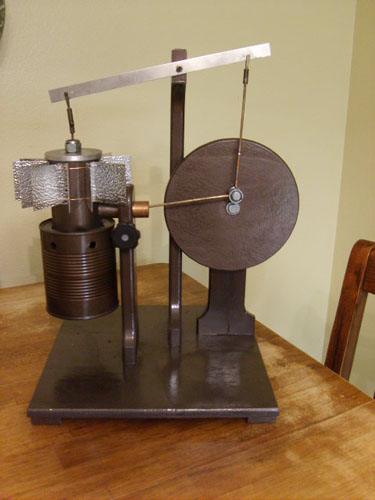

John_Schedler

built built

Aug 2009

|

-Base

measures 14" X 14"

-Engine stands 24" high

-This engine runs off of Chafing Fuel.

-All joints are silver brazed

-There is a regenerator in this engine.

-The crank eccentric has a hole in it to accept a drive shaft and will

have a

small fan blade fitted to it.

-The piston is machined and measures 1 1/16" in diameter.

-Stroke is 2 3/8"

-Displacement cylinder is a Lysol can with standard tomato paste can

inside.

-Air-cooling provided by aluminum mat slats secured by hose clamps.

Cooling

capacity far exceeds needs.

-Running RPMs: 140 - 160

This engine will run for approx. 3 hours from one chafing fuel

container.

Build time is about 55 hours. The tolerances are close and this

engine is

extremely quiet. I lube it with sewing machine oil.

John Schedler

|

Additional Photos

Photo #1 Photo #2

Richard Dales

Built Jan 2008

|

Power cylinder is 15mm copper water pipe.

Power piston is JB Weld epoxy (tolerates

c.350 deg C?)

Crank is coat hanger wire Flywheel is a CD, centred onto the crank

using screw

top from toothpaste tube. A small coin balances the flywheel against

the weight

of the displacement cylinder.

Expansion and displacement cylinders are

aluminium

Guinness cans.

Small bits of steel from top of a baked

been tin were

used for the three points where wires pass through holes.

The three Aluminium cans are cut with

ruler and Stanley

knife, or scissors where appropriate.

By rubbing the inside edge of the cut

cans hard against

my vegetable chopping board with a teaspoon I found the each can could

be

easily pushed inside the next. A tiny bit of JB Weld ensured a good

seal.

Lubrication used was olive oil, but

sowing machine or

hair trimmer oil would have worked better.

Richard Dales

|

Matthew Shippee

Built 2009

|

While

this is not a walking beam stirling, I could never have gotten it

working

without info from your site and plans.

There

are also several videos on youtube (mrweaseluv) that you might like to

link to (3rd and best video will be up tommorow with a little luck)

And a word of advice to new

modelers, a ball bearing in matching bearing tube

makes a great airtight power piston :D (attaching the bearing to the

rod is the

fun part hehe)

Matthew

Shippee

|

Paul Maciulaitis

New Zealand

|

Here's my bigger version of your tin

can engine. It still needs refinements like better cooling later on.

The power

piston cylinder and crank was a 2hp briggs and stratton

i fitted

teflon gland packing for rings and drilled out the spark plug hole and

fitted a

1" pipe fitting. The displacer is an old air tank and the firebox is a

peice of stainles chimney almost all bearings are roller it goes about

50/60

rpm.

Heres a link of it running on kindling wood http://www.youtube.com/watch?v=6tHtlx3VbqM

anyway thanks the small one is still going good

Paul Maciulaitis

|

We're Cooking Now!

Magnificent Works of Art!!!