Boyd's Tin Can Stirling's

Hot Air Stirling Engine Web

Page

Hot Air Engine, Stirling

Engine,

External Combustion Engine, Stirling Plans, Hot Air Engine Plans,

Stirling

Walking Beam Engine, Sterling Engine (oops!)

www.boydhouse.com/stirlings

"True"

Horizontal

Tin Can Stirling Engine

Most

tin can engines either have their displacer piston and power piston in the

vertical posision.

Or as in the walking beam tin can it has one in the vertical posision

(displacer piston) and one in the horizontal posision (power piston).

This is the first tin can engine to place both the displacer piston and

power piston in the horizontal posision.

Making it a "true" horizontal tin can stirling engine.

Disclaimer (sort of )

| I would build the "Walking

Beam Stirling Tin Can Engine" first if this is your first engine.

There

is more details and hints that are very helpful to the first time tin

can

builder.

If you have already build a working ,

then

you will be able to figure out how to build this one. Close to the same

as the "Walking Beam Stirling Tin Can Engine" with a few major changes.

You're on your own!!

|

This projected started with a "Walking Beam"

engine

displacer cylinder ,power cylinder,

and displacer I started and decided not to finish.

Instead I decided to make a "true" Horizontal engine out of it.

Reworked displacer piston. Note rod is steel not brass and

goes through the displacer and out the bottom 5 1/2".

Brass rod sags too much and a steal rod eliminated this problem.

View of top bearing of Displacer Cylinder.

Same as the original "Walking Beam" engine.

Reworked displacer cylinder. Note brass tubing silver soldered onto

the bottom to help support the displacer piston.

(This is not the finished design. See below)

Displacer piston is slid into the displacer cylinder and top is

then added

(This is not the finished design. See below)

Top is then soldered on

(This is not the finished design. See below)

Changes !!!

| After some consideration, I decided

to make

a few changes.

1) On the bottom or to the left I

removed the

brass tube and replaced

it with a brass bolt with a 1/8" hole

down

the middle just like the top bearing. I was concerned with the extreme

heat melting the solder and releasing the brass tube bearing. This

"bolt-in"

approach removes this possibility.

2) I made a temporary brace to help

hold the

power cylinder straight and true while soldering. I wired this on.

|

Temporary brace and wires were then removed.

Displacer cylinder was installed and top was soldered on.

Painted with high temperature black paint.

Another good photo of the "new" bottom bearing.

Good photo of the top bearing. Same as the "Walking Beam" Engine.

Phase 2

Some

alterations were made.

The old copper

pipe was removed and a new style power cylinder and piston was installed

.You can see

the new style cylinder here

Some

alterations were made.

The old copper

pipe was removed and a new style power cylinder and piston was installed

.You can see

the new style cylinder here

I added a 90 degree elbow fitting to

the back of the new cylinder

I added a 90 degree elbow fitting to

the back of the new cylinder

The water cooler tin can was

hole sawed out and fitted on the displacer.

Then it was attached using red hi temp

silicone sealer. You can get this at any auto parts store

I used a U bolt from Orchard Hardware

for mounting front and back.

I used a U bolt from Orchard Hardware

for mounting front and back.

Copupling nuts at the bottom with flat head machine screws will mount

from under the wood board when mounting.

Picture of front U bolt setup

Picture of front U bolt setup

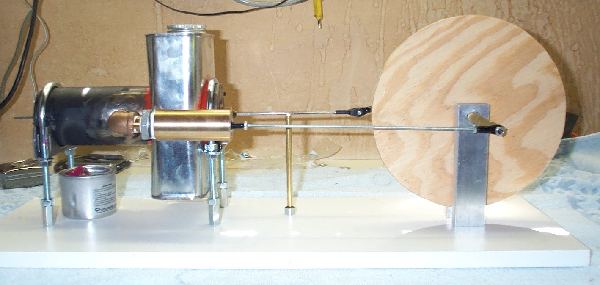

Ready to mount to a board.

Ready to mount to a board.

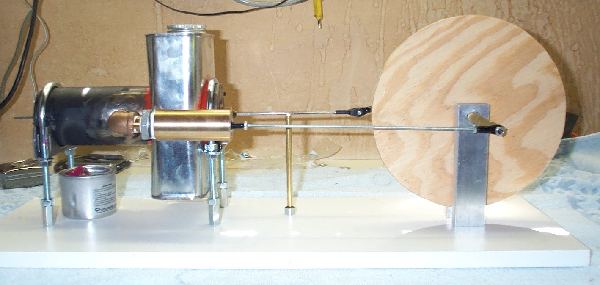

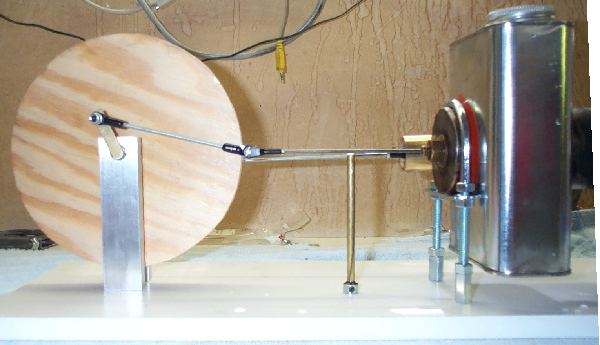

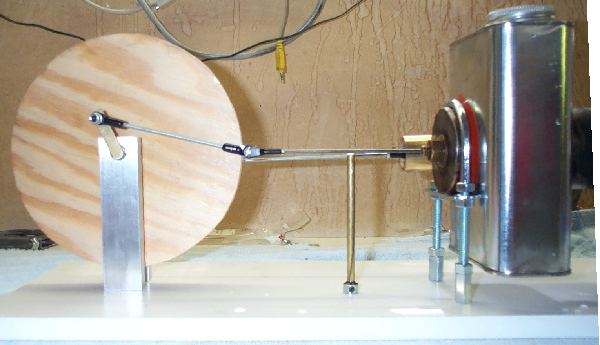

Here it is mounted to a shelf board.

Close up of the power piston just hanging out just a little.

I used a rod end from a hobby shop on the power piston.

Now for the fly wheel!

Phase 3

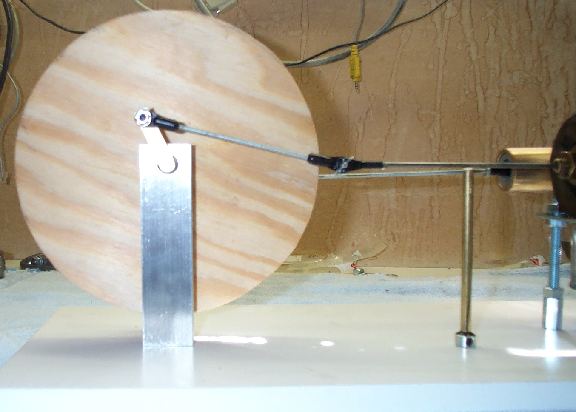

Almost done. In this phase (at the end) I fired it up. It would make

about 3 to 4 cycles and then stop.

More on that later!

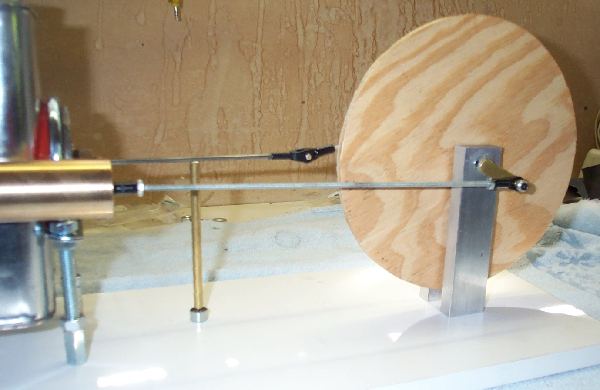

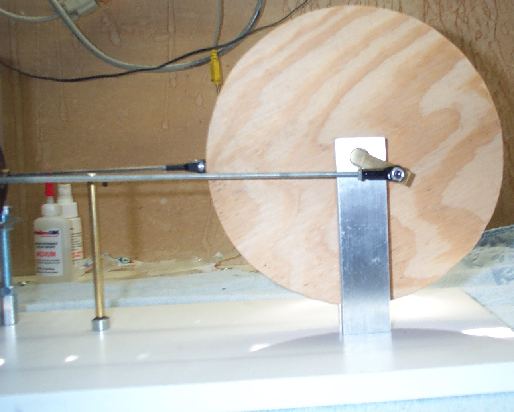

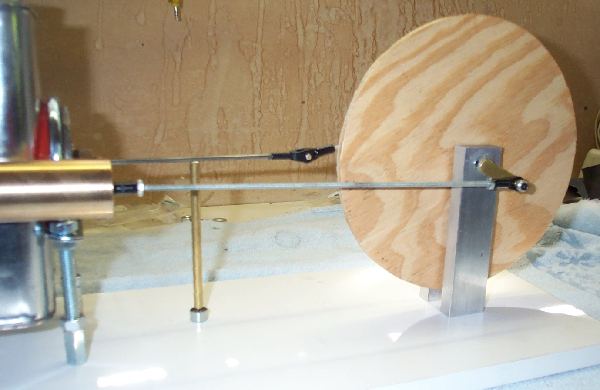

I used tie rod ends from RC planes to make the connecting rod

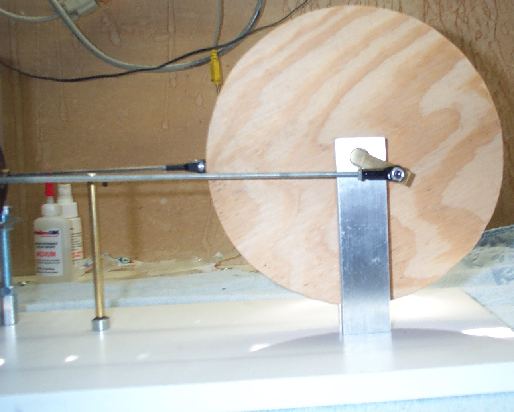

I used RC rod ends and clevises to make the displacer rods. I had to

support the rod coming out of the displacer

cylinder with a brass rod. This made the rod go in and out easier

without binding.

A better view of the same rod

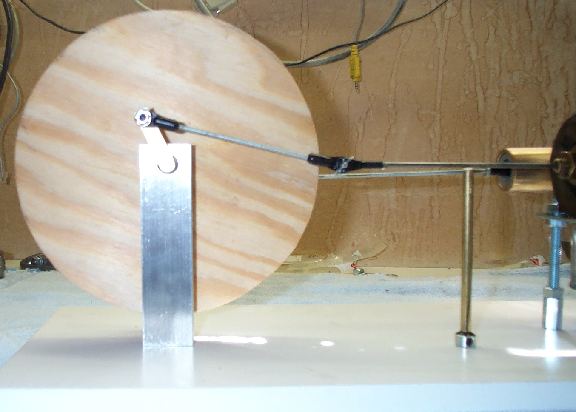

As I said earier, I fired it up and it would go about 3 or 4 cycles and

then stop. I removed

the piston rod from the flywheel crank and turned the flywheel around

creating "cycles".

The piston would push out and pull in just as it should, but I feel it

should have a little more power.

Problem?

I think the main problem is not enough heat getting to the rear of the

displacer cylinder.

As you can see I have no "hood" around the displacer cylinder to direct

the heat evenly around both

sides of the cylinder (outside). I think if I fabricated a hood it

would heat more evenly. I was able

to get more power by moving the Sterno can back and forth or from side

to side. This heated the engine on

both sides more, but even would be better. (no I didn;t use the

entire can of Sterno. That is an enpty can with the lid on it.

The Sterno was placed on top of that to get the fire closer to the

cylinder.

The second proplem is......Tha big honking "U clamp" in the rear. I

think it might be sucking up a lot of heat. Sort of like

a heat sink. I think I might move that forward all the way to the water

tank as close as possible. That might help a bunch also.

Still over all. 4 cycles is not too bad for a first attempt!

Phase 4

The

Final Phase?

"I've got to have more power!"

OK, moved the mounts (pipe clamp) forward in front of the power piston

exit and made a fire box.

The fire box was made from another can (like to stay with the program)

and installed.

Ran great for about 2 to 3 minutes then everything broke loose....well

exploded to be exact.

You will notice the small can of sterno on the left of the photo above.

That can had it's lid on

and sterno on top of it to place the fire closer inside the firebox. Very bad idea!

After running about 2 to 3 minutes that can heated up (DUH!) and

exploded. That is why the lid is off

and the fire box is turned a little sideways. Didn't even see that one

coming! Can was still on fire be it almost out.

Notice I thoiugh about removing the cap of the water tank. I though to

myself.....

better remove that cap, don't want this thing building up pressure or

steam and blowing apart!

Almost had it right!

Firebox removed from rear of engine

Still it ran for some time there. I need to work on the timing a little

and a new way to deliver the fire into the fire box.

That's it! I don't see a PHASE 5!

Return

to main page

© 1999-2003 Darryl Boyd, All rights reserved

Comments can be

directed to