|

Disassembly

and Cleaning

When you get a Mosin you need

to know how to disassemble it and do a complete initial cleaning.

Taking the Mosin apart is easy and can be accomplished with just a

screw driver. Remember, you are not a trained gun smith nor do you or I

play one on TV. and we darn sure didn't stay in a Holiday Inn Express

last night! So, what we will be doing is performing field maintenance.

Although some of you may be very experienced in fixing up firearms, try

to remember that these rifles are old and age is not kind to metal or

wood. A 50 year old stock is going to be as dry as firewood and very

brittle. Forcing out a band spring can be all it takes to crack the

stock. Likewise, a cross bolt that is been in the rifle for 50 years

may be stressed just enough to snap. On war time produced rifles, the

metal can be of lesser quality.

Note: Read Everything On This

Page!!!

Lets talk about what needs to

be disassembled.

First

of all there is no reason to mess with the cross bolt or barrel band

springs. Attempting to remove the cross bolt can result in its

breaking. Removing the band springs can result in a cracked stock if

not done correctly. We have beat this to death so lets move on...

To do a good inspection and

cleaning, you will need to get the metal pieces separated from the wood

pieces. Some of the instructions that follow will be model dependent so

keep that in mind. Depending on the model, the pieces-parts disassemble

differently. For now we will discuss the process in generic terms. The

first thing you do when ever you pick up a rifle is to open the bolt

and inspect the chamber to ensure it is not loaded! Each and every time

you pick it up, you open the bolt, hold the rifle up so that you can

see into the chamber (tilted slightly and at a 45 degree angle) and

visually check the chamber. After you have satisfied yourself that it

is not loaded, you grab the rear of the open bolt while pressing on the

trigger and pull it back and out of the receiver.

Set the

bolt aside. At this time, you will remove the hand guard. Remember I

said some information is model specific? No? Well pay attention dammit!

I said that and if you read this article over you will see where I said

it. No, don't start reading it over now! Take my word for it...anyways,

here's the deal. If your rifle is a Model 1891, Model 24 or other M91

variant, it will have different barrel bands than the more modern

Mosins. The barrel bands will have a screw in them. Now here's the

deal, these screws are backwards from normal screws. To loosen them,

you need to turn them clockwise. Stop! Don't try to think about it now,

just pay attention...that means that they unscrew in the opposite

direction a screw would normally unscrew. Why is this important?

Because I get all this mail from folks who break their band screws. Do

not break your band screw! It is embarrassing and finding a new barrel

band can be darned difficult. Another thing, these barrel bands on the

M91 type rifles were often pinned to keep the bands from creeping

forward under recoil. Check to see if there is a pin or tiny screw

inserted next to the barrel band and remove that. If it is a screw,

this screw will unscrew in the normal fashion. Once you have the barrel

bands unscrewed just enough to slide forward, remove them. Oh, did I

mention that if your rifle has a cleaning rod to go ahead and remove

that first? No? Well I didn't and I was just trying to see who was

paying attention! After you remove the barrel bands, remove the hand

guard and set it aside. Never mind gawking at the naked barrel, you

have work to do and there is plenty of time to do that later!

Now, about barrel bands and

later model Mosins...Again this will be model specific. On converted

Dragoons, carbines, 91/30's and later constructed Mosins of other types

like the 91/59 and 91/38, the barrel bands are held in place by the

band springs which are under them and recessed slightly in the wood.

They push up against the barrel bands to keep them tensioned so that

they hold the hand guard on. They also like to collect all kinds of

crap underneath them which makes it hard to depress them to remove the

barrel bands. Your first task is to determine how much crap is under

there and remove it. Push down on the band spring. Push hard because

this isn't a job for the wimpy! If it resists depressing, get your self

some round tooth picks and a syringe filled with hot water. Grab the

one your significant other's or mom's that she uses in the kitchen.

Just don't let her find out about it! Inject a strong stream of hot

water under the barrel bands. Why hot water? Well, it will help to

dissolve grease and cosmoline and will flush out loose crap. It will

also dry faster and be less prone to corrode the band spring. Now, take

your tooth pick and dig around as best you can under the spring and

pick that crud out of there. Once you are satisfied you got all you

that you can, try depressing the spring again. It should depress enough

to allow you to slip the barrel band over it. If it doesn't, we go to

plan B. I didn't tell you about plan B yet you say...well of course I

didn't because everybody knows that B comes after A and we weren't

there yet!

Plan B is the screw driver in

the cleaning rod trick and it takes a little finesse to keep from

scratching the heck out of your stock. First, obtain a flat blade screw

driver no wider than the cleaning rod channel. Turn your rifle upside

down so that you are looking down at the cleaning rod channel. What's a

cleaning rod channel? Its the slot were your cleaning rod was under the

stock. Take your screw driver and a couple of cleaning patches. Fold

the patches over the tip of the screw driver and insert the screw

driver behind the barrel band between it and the wood of the stock

behind the rear band. Do not force it! Wiggle the barrel band far

enough forward to get the screw driver behind it. Now, this takes some

talent because you are going to balance the rifle in your lap, while

holding down the band spring with one hand and using the screw driver

with the other to ease the band forward over the band spring. You need

to do this in stages. Pry a little bit as you press down and then while

still pressing down, push the opposite side of the band so that it does

not bind on an angle. Keeping this up, gently walk the band over the

band spring. I say gently, but realize that this will take a little

force because what you will be doing is spreading the band spring a

little. If you were paying attention to what you are doing, you would

have noticed that the band spring is not connected underneath therefore

it can spread apart. Again, don't mess up your stock while you are

doing this!

You can do the same thing

with the front band. Now, remember I mentioned model specific

differences? No? Well wake up! I did and here is another one. You

cannot completely remove the barrel bands on a M44 Carbine. Don't try

and as a matter of fact don't even think about it and don't write to me

asking how to take the bayo mount/front sight assembly off to do so

because that is even a dumber idea! Just slide the darned things down

towards the bayo mount so you can remove the hand guard.

Now

that we have the hand guard off, we can turn our attention to

separating the metal from the wood. Look at your rifle from the top.

See that area where the bolt was? At the very rear of that area as you

look down, you should see a screw head sticking out of the tang. You

can't see the screw because the bolt is in the way? I thought I told

you to remove the bolt? Failure to follow instructions is the sign of a

weak mind so next time pay attention. Now go ahead and remove the bolt

and look down there.

Using a larger flat blade

screw driver, remove this bolt. Turn the rifle over. Just in front of

the magazine, you will see another big old screw head. Remove this

screw but make sure you are holding on to the barreled receiver (the

metal stuff) because the barrel and receiver may just drop right out in

your hand.

However it may not until you

grab hold of the magazine and give it a sharp pull to remove it.

After

that, the barreled receiver should just drop right out but don't let

it! Remove it slowly because there just might be shims in there that

you need to note where they were.

Most

likely they will be under the pillar or the tang. If there was a shim

in the pillar area, note if it was behind the pillar or under the

pillar with the bolt that you took out running through it. Set these

aside and don't loose them because I won't be telling you how to make

new ones in this article. After you have removed the metal from the

wood, set the wood aside for a minute because we are going to check out

the metal. Start at one end and look for signs of active rust. Active

rust will be brown or reddish in color. Check the receiver part

(everything that is not your barrel) for cracks or deformities. Inspect

the barrel for deep pitting and bulges. Deep pitting is anything that

is deeper than your little brother's acne scars. Anything else should

be checked by a gun smith. Of course a bulged barrel means that you

have a wall hanger. After inspecting the outside of the receiver, it is

time to get down to cleaning it and the barrel. See the Cleaning

article.

Dave's Bolt Disassembly Article

Before

attempting any type of activity with a firearm you must verify that the

firearm is unloaded and safe to handle. Be certain that both the

chamber and magazine are empty. Check again. It is also an excellent

idea to handle firearms in an area without access to ammunition so that

accidents can be avoided. Even if you have verified that the firearm is

not loaded, always assume that it is loaded and ready to fire and

handle it appropriately.

In the case of military surplus firearms, a thorough check by a

qualified gunsmith is critical prior to using the firearm for the first

time. The procedures and opinions presented in this article are not

meant to take the place of a professional gunsmith's services and are

presented only for the education of the reader.

After

assembling the bolt of a Mosin Nagant firearm it is extremely important

to verify firing pin protrusion before firing. A tool is

available that performs this function form most distributors (see photo

and comments below in the text).

The Mosin Nagant bolt is

frequently referred to by the uninitiated as over-complicated, poorly

designed, roughly finished or just plain ugly. I must admit that,

before becoming familiar with the Mosin Nagant series of rifles and

their history, I too considered the bolt to be old fashioned and unsafe

looking. The simple fact was that I had not learned to appreciate the

bolt design for what it is – an incredibly efficient, robust design

that is actually simple and easy to understand. This unusual

organization of seven pieces of steel has withstood the test of time,

battle and extraordinary political change.

In addition, unlike many

parts of the Mosin Nagant series of rifles, the bolt has remained

almost exactly the same – no matter if the firearm is an 1895 M91 or a

mid-1950’s M44. Although aesthetic differences do exist between the

various manufacturers, what other firearm design can claim a bolt

design that remained essentially unchanged through its entire service

life – of approximately 100 years! By unchanged I mean that nearly* any

piece of the Mosin Nagant bolt can be interchanged without modification

with a bolt from another Mosin Nagant rifle.

*NOTE: Although bolt heads

can be interchanged, the rifle’s headspace must be verified after such

a change is made. In addition, because bolt heads are not generally

marked with identifying numbers to match them to a specific receiver,

it is critical to have the firearm’s headspace checked by a

professional before firing a Mosin Nagant for the first time. This is

true even if the bolt body has a stamped serial number matching it to

the receiver. Remember, these rifles have been around for a long time

and parts may have been swapped (perhaps many times) before you

received the firearm. Safety first!

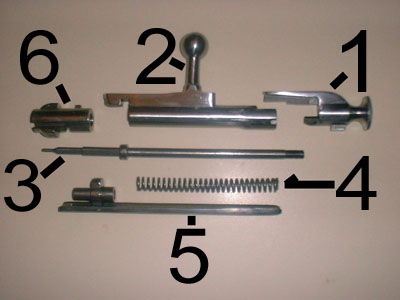

The

bolt is made up of seven individual pieces:

1) Cocking piece

2) Bolt body (also called the

bolt handle)

3)

Firing pin

4) Main spring

5) Connecting bar

6) Bolt head and extractor (2

pieces)

SAFETY

CHECK!

SAFETY

CHECK!

Take

it from someone that learned the hard way - the firing pin is under

considerable spring pressure. If the firing pin is unscrewed from the

cocking piece without being held in place, it may (will) fly in an

unpredictable direction and cause damage to itself, you, or a

bystander. Follow the directions below carefully and wear eye

protection.

Never disassemble more than one bolt at a time. This will prevent the

interchanging of parts, particularly bolt heads.

Disassembly

There are a number of methods

to disassemble the Mosin Nagant bolt, all of which work and each of

which has its advantages and disadvantages. The method I use does have

an element of risk, in that the firing pin can be broken when the

spring is compressed and the cocking piece is removed. Read the entire

set of instructions carefully – if you are not comfortable with each

step – and the possibility of breaking a firing pin if your hands slip

(in Step 5), do not attempt this procedure.

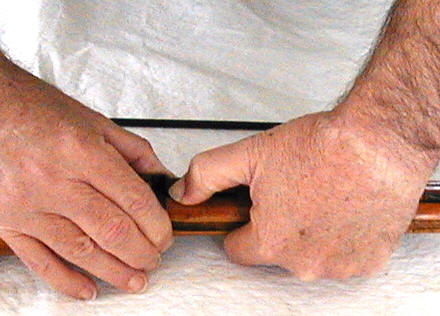

STEP 1: While

holding the bolt in your left hand as shown above, grip the cocking

piece with your right hand and pull it toward you slightly. Turn the

cocking piece counterclockwise ¼ turn and then gently let the cocking

piece move away from you. Keep the bolt head pointing upward or it

could fall off of the bolt body!

STEP 2: The

bolt should now look like this. I call this the bolt's "fired

position". Continue to hold the bolt head end upward!

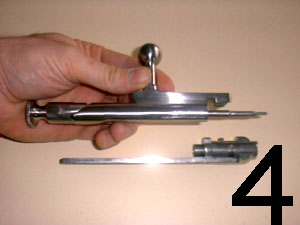

STEP 3:

Hold the bolt as shown and pull the bolt head and connecting bar away

from the bolt body.

STEP

4: Put the bolt head and connecting bar aside. Now

for the hard part…

STEP 5:

This is where you can break the firing pin. The photo above shows

several “dimples” in my kitchen table that were created when I took the

photography for this article. My wife does not know where these dimples

came from and blames the kids. Please do not tell her the true story.

Any HARDWOOD surface will suffice for this step, but be thoughtful of

your marriage when selecting the “right spot”. Do not use metal – the

firing pin will skid and (possibly) break. Softwood will not support

the pressure and the firing pin will probably sink into it like a nail

(and possibly break).

While holding the bolt body

in your left hand as shown, maintaining a perfect 90 degree angle from

the hardwood surface, push down on the bolt body, thereby compressing

the spring, until you can turn the cocking piece in a counterclockwise

direction without hitting the bolt body. This is a somewhat awkward

procedure and considerable downward pressure on the bolt body is

necessary.

Continue turning the cocking

piece in a counterclockwise direction until you can remove it from the

firing pin. SLOWLY raise your left hand and gradually release the

spring pressure on the firing pin. When the pressure has been

completely released, remove the firing pin and spring from the bolt

body.

Hey –

you did it!

Clean all of the parts while

you have them apart, with special care not to forget the inside of the

bolt body and the inside of the bolt head. Lightly lubricate the firing

pin, spring and internal surfaces; however, try not to get any oil on

the exterior of the bolt body. Your hands might slip later if you do…..

Assembly

STEP

6: Put the spring back on to the firing pin and

insert both (as shown above) into the bolt body.

STEP 7:

As in step five, while holding the bolt body in your left hand as

shown, and while maintaining a perfect 90 degree angle from the

hardwood surface, push down on the bolt body and install the cocking

piece onto the firing pin by turning the cocking piece in a clockwise

direction. After you have turned the cocking piece clockwise three full

revolutions onto the threads, SLOWLY raise your left hand and gradually

release the spring pressure on the firing pin.

STEP 8:

SAFETY

CHECK! SAFETY

CHECK!

Keep

the firing pin pointed away from anything important (such as your face)

and wear eye protection. I have mistakenly turned the firing pin in the

wrong direction in step 8, and it will fly off in a random direction if

you do this. Safety first!

Hold the bolt as shown above,

and using the connecting bar as a wrench (as shown above), turn the

firing pin CLOCKWISE until….

STEP 9:

…the rear of the firing pin is flush with the cocking piece and the

index mark is aligned, as shown above. Be certain that the cocking

piece is in its “fired” position (turned 1/4 turn counterclockwise; see

step #2). If necessary, adjust the firing pin again using the

connecting bar as a wrench (see step #8).

STEP 10:

Put the bolt body assembly aside for a moment and pick up the

connecting bar and bolt head. While holding them as shown above, slide

the bolt head on to the end of the connecting bar…

STEP 11:

…and turn it ¼ turn counterclockwise to the position shown above.

STEP 12:

While holding the bolt body assembly in your left hand and the

connecting bar/bolt head in your right hand as shown above, slide the

connecting bar/bolt head onto the bolt body. Make certain that the

connecting bar’s left end mates with the “nub” (cocking notch) on the

cocking piece.

STEP 13:

This is what you should end up with. While holding the bolt head and

connecting bar in place on the bolt body…

STEP 14:

…rotate the entire assembly and hold it as shown above. Grasp the

cocking piece in your right hand, and while continuing to hold the bolt

head in place, pull the cocking piece toward you and simultaneously

rotate it ¼ turn clockwise…

STEP 15:

…until it clicks into place as shown above.

You have successfully

assembled the bolt!

SAFETY

CHECK!

SAFETY

CHECK!

Be

certain to check the firing pin protrusion using the screwdriver /

protrusion tool found in a standard Mosin Nagant Cleaning

kit. If you do not have this tool, the cleaning kit is well

worth the money and can be obtained from most of the better known

Internet firearms vendors. Failure to check firing pin

protrusion can result in insufficient protrusion and the

awful "click........". Excessive firing pin protrusion can

result in pierced primers and a sudden release of high pressure gas

into the receiver. Both situations are extremely dangerous

and can cause severe injury or death to you and

bystanders.

A

future article will explore the details of checking firing pin

protrusion; however, a brief summary is necessary. First,

verify that the bolt is in its "fired" position and that the firing pin

is flush with the cocking piece (see step 2, above). The

index marks must be aligned.

Second,

as shown below, the firing pin must (at least) touch the top

of the milled out area below the number "75" on the protrusion

gauge. If it does not, firing pin protrusion is

insufficient. Be certain that there is no gap between the

bolt head and bolt body (hold them together) when performing this test.

Finally, the firing pin must *not*

touch the top of the milled out area under the number "95".

If it does, firing pin protrusion is excessive.

Although it is possible to

adjust firing protrusion in the field, a matched bolt should not have

this problem, assuming the firing pin and the cocking piece are flush

and the index marks are aligned. A bolt failing the

protrusion test under these circumstances is suspect and must be

checked by a qualified gunsmith.

Bottom line: Be

safe and use common sense!

The

links section of the site contains many vendors selling protrusion

gauges; however, feel free to email me if you cannot locate a vendor

selling them. I will email you a list.

Dave/Col9

collector9@usa.net

Cleaning Your Mosin

Now that you have

successfully disassembled your Mosin, you are ready to clean it. You

don't have it disassembled yet? Well go back and do it and make sure

you read the article and not just go and try pulling it apart on your

own! There are reasons for this other than increasing my page hits!

Now, for the rest of you that

have properly disassembled your Mosin, lets talk about cleaning it.

First of all, we want to clean it while preserving its collectable

status. Using improper cleaning methods can destroy its value as a

historic firearm. What do you mean its not historic because its just

another old M44? Don't get me started! Just go look in your gun safe or

closet and tell me how many 1903 Springfield rifles are in there or how

many Mausers with all matching numbers and Waffenampt stamps? Probably

not a heck of a lot because you can't find them any more. There were

millions made and they were all either placed in collections or messed

up and destroyed through home workshop projects and improper cleaning.

Your M44 might be cheap rifle today but twenty years from now, it could

be one of a hand full on the open market when you get ready to sell it

for the money to pay your nursing home bill! Even though it might be

mismatched, if you knew your Mosin history, you would know that when it

comes to Mosins, they are expected to be mismatched. Now where the heck

was I? Oh, yes...cleaning and preserving the rifle's value. The first

rule of thumb is (repeat after me...) Do No Harm. Do not do anything

that will harm the finish of the rifle, it's markings or stock

cartouches. Try to keep the original finish intact if at all possible.

This means we need to select cleaning materials that are

non-destructive.

So

there you are with all of your Mosin parts spread all over the kitchen

table and you are getting nasty looks from your significant other or

parent. Hopefully you remembered to put a drop cloth or news papers

down first! If not, don't blame me because I am not responsible for

your having your head up your forth point of contact! Now, lets

approach what materials we will need based on what we need to clean.

For the stock, you will need a non-abrasive, non-volatile cleaning

product that will not remove the finish from your stock. Since finishes

are either oil based or alcohol based, we need something that will not

contain petroleum products or alcohol. I like to use Orange Clean or

any other citrus based cleaner. It will cut the grease and cosmo

without harming the finish. You will need plenty of rags or paper

towels and plenty of elbow grease to get the gunk off. For the metal,

you need a good degreaser like break cleaner or Gun Scrubber. You also

need some a solvent like paint thinner, turpentine or good old

fashioned kerosene. Don't know where to buy kerosene? Look no farther

than your corner gas station as diesel fuel is nothing more than

upwardly mobile or refined kerosene. Once you have your cleaning

products assembled, you can get started on the cleaning.

The stock, spray an area of

the stock with your citrus cleaner and remove the larger portion of

crud and cosmolene. Methodically cover the the entire stock and get the

major crud off and then go back and clean the rest and pay attention to

getting the crud from around the outside of the cross bolt and out of

the band spring inlets. Use a toothpick to for this job as it won't

harm the finish. Allow the stock to dry.

While the stock is drying,

spray the receiver and barrel as well as the magazine assembly inside

and out with a degreaser. Wipe down the outside and then run a cleaning

rod with a patch through the barrel to push the crud out of there. Go

back over the inside and outside of the receiver with your degreaser

and get the film off from it. Use your break cleaner to spray into the

feeder/interrupter assembly to clean that. If you are really

adventurous, you could disassemble that and the trigger assembly and

clean these parts separately. Soak a patch in your break cleaner and

run it through the bore to clean the residue out of there. Now, grab

your chamber brush...what? You mean you don't have a chamber brush?

Well go get one because you are going to need it. Did you read my list

of Mosin tools? While you are at it, if you don't have one already, dig

out your three piece cleaning rod and attach the chamber brush to just

the handle piece as you would attach a jag for pistol cleaning. Squirt

a health amount of break cleaner into the chamber and scrub the heck

out of it with the chamber brush! Make sure the brush contacts every

nook and cranny in there. Concentrate on the locking ring area and the

chamber walls. When these rifles were placed in storage, they were

packed with cosmolene. Over the years that cosmolene dried out and

formed a nearly transparent film in the chamber. If you don't get that

film, it will cause you all kinds of hassles later on with extracting

rounds that are lacquer coated. When you are thinking it is clean,

scrub it some more and then finish off with your chamber brush

liberally soaked with Sweet's 7.62. I can't say enough about this

product. It is the best bore cleaner on the market and it does an

outstanding job on the chamber.

Now,

before you go to the fridge for your favorite beverage or pour yourself

a cup of coffee, get an old pan and fill it with solvent and toss your

bolt parts and magazine assembly in there and let them soak. Go ahead

and release the floor plate latch of the mag assembly and remove the

floor plate by pinching it like one of those spring clothespins. Dump

everything in th solvent. Go enjoy your coffee, smoke a butt or play

with mamma and get back here to finish up. Done already??? Heh, heh,

gettin' old huh? Well no matter...back to the bolt. All of those bolt

pieces are hollow from the bolt head to the bolt guide, the bolt body

and the cocking piece. That means that there are plenty of places for

crud to collect. Get yourself a small Phillips screw driver (star point

if you are from Podunk) and stick a patch on the end of it. Pull the

bolt head out of the solvent it was soaking in and stuff that patch

inside it and rotate it. You might have to get something to hook the

patch back out with. Give the bolt head a final squirt of break cleaner

(inside and out) and dry patch it. Do the same thing with the bolt

guide, bolt body and cocking piece. when you are done, the metal should

be dry and free of any oily or greasy film. Do the same thing

with the magazine assembly. Coat everything with a light coat of your

favorite gun oil. Pull the spring and firing pin out of the solvent and

spray them down with the break cleaner and wipe dry and coat with gun

oil too.

Now before you get all

excited and want to put everything back together again, don't forget to

clean the bore. Remember we only got the crud out but we didn't do any

serious cleaning. I like to start out by using Sweets and I run several

patches through to get out the last century's worth of copper fouling.

What? You said the dealer told you this rifle was un-issued? Yeah,

ok...if you want to believe that go ahead but trust me, use the Sweets.

You will be surprised at what comes out of your bore. Now if you look

down that puppy and it looks a little dark, I might suggest picking up

some J&B Bore Paste not to be confused with JB Weld!!!

Remember, J&B Bore Paste....are you

listening to me??? Quit thinking about getting your gun out to the

range and pay attention....J&B Bore Paste!

Use as directed and you will be happy you did. I have resurrected some

real sewer pipe bores with this stuff.

Now we are ready to put

everything back together so clean up your mess before you end up

sleeping in the garage and put your cleaning stuff away and go back

back to the Disassembling Your Mosin Article.

Reassembly

For reassembling the bolt see

Dave's article above.

OK...now, pick up your stock

and the barreled receiver. Hold the stock in a horizontal upright

position. If there were shims in there before, put them back to where

they were. Now pick up your receiver and lower it into the stock.

Turn the stock over

and put the magazine assembly back on.

OK...now, pick up your stock

and the barreled receiver. Hold the stock in a horizontal upright

position. If there were shims in there before, put them back to where

they were. Now pick up your receiver and lower it into the stock.

Don't forget to reattach the

floor plate. Make sure the mag housing is seated properly and pinch it

against the receiver assembly by squeezing it and the top of the

receiver with the stock in between and drop the mag housing bolt in and

hand tighten.

Now rotate the rifle right

side up and drop in the tang bolt and tighten with a screw driver and

go back and tighten the magazine bolt with a screw driver.

Now

you are ready to put the hand guard back on. Place the hand guard on

top of the barrel and line it up properly.

Take the rear barrel band

because it would be pretty dumb to put the front one on first and make

sure the joint is pointed down and slip it past the front band spring

and slide it back to rear and over the rear band spring until it clicks

into place.

Now do the front band.

Remember

the model specific stuff we mentioned before? On your M91, slide the

rear band on with the crack pointed down and the screw head on the

right side of the barrel as you are looking down range. Slide it all

the way back and replace the pin or screw you removed earlier. Don't

tighten it yet. Do the same with the front band. You did remember to

put the hand guard on first didn't you? Now you know why I said not to

tighten it yet! Now, you can tighten the rear band by turning the screw

which way? Well...I'm waiting? Don't look up there on the page, you

should know this by now! That's right...clockwise! Same goes with the

front band.

Now, replace the cleaning rod

and screw the darned thing in so it doesn't come snaking out of its

hidey-hole while you are shooting the rifle at the range!

When you are done with that,

you can reinsert the bolt by depressing the trigger and sliding the

bolt home.

Now....look at the table and

tell me if there any parts left over?

If there aren't, you are done! If there are, go to

the top of this page and start over.

|