|

8’ Loop

X-tal Set

by

Josh Young

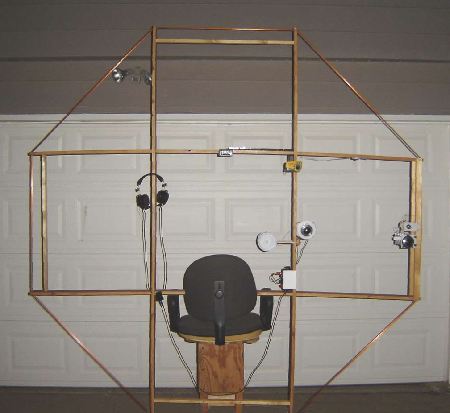

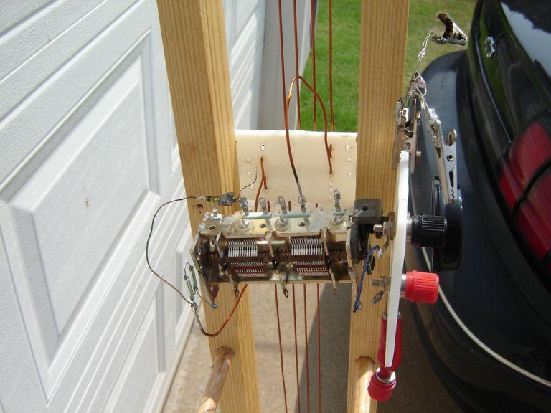

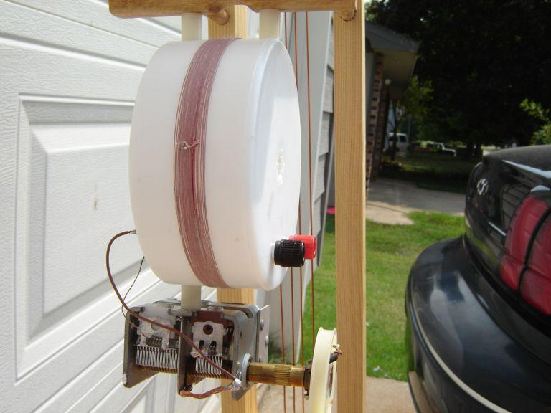

Overall size, and how the set looks when it

is in use on it’s homemade chair/stand.

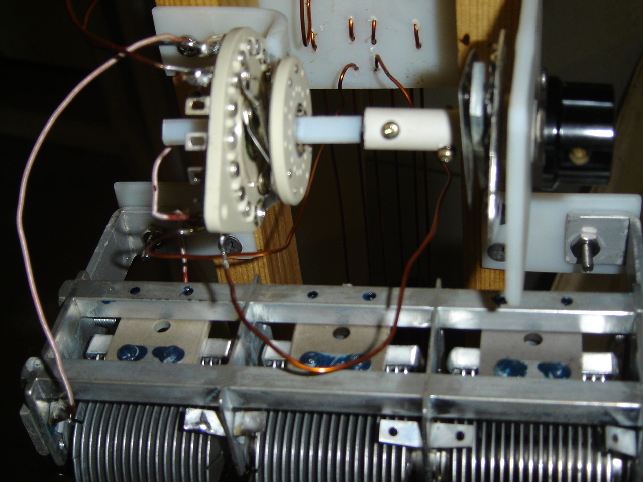

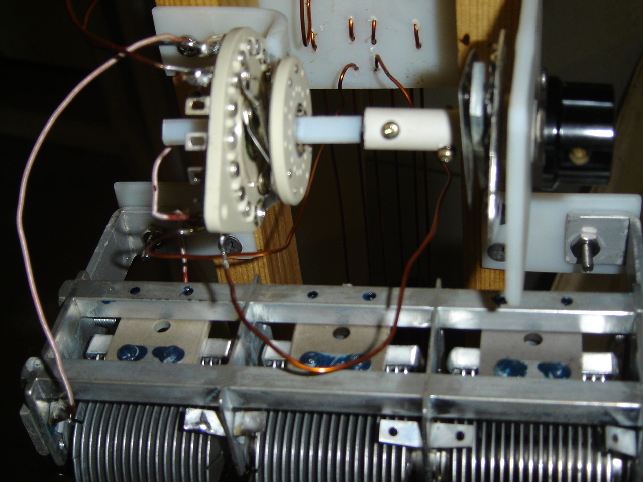

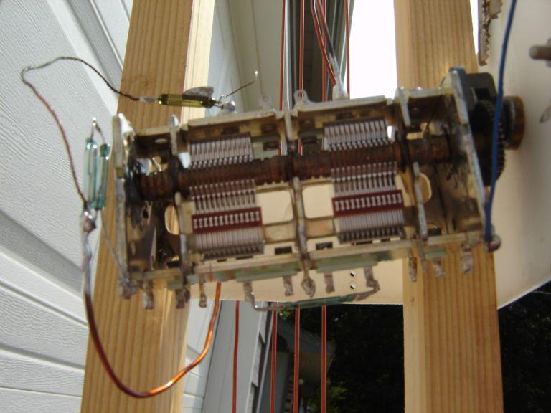

Up close of the “Control

Center”.

You can see the Series/Parallel

switch for the main loop on the right hand side.

Notice the Digital

Spotter Radio, LED Light( above the VC’s on the horizontal spreader),

Notice the Digital

Spotter Radio, LED Light( above the VC’s on the horizontal spreader),

Clock, and Slide-In Transformer box holder.

|

8' Loop Crystal Radio

by Josh Young

About eighteen

years ago my

Grandfather introduced me to crystal radio fun.

He told me some really neat stories of receiving long distance stations

with no batteries or power. Ever since

he bought me my first Radio Shack Crystal set I have been hooked.

I have been experimenting and tinkering with

them off and on for about 16 years, and I am continually amazed at

their

performance. I can’t say exactly when it

happened, but along the way somewhere I got interested in Loop

X-tal sets. My first Loop

made was a “X” frame made from some cheap wood and a scavenged Variable

Capacitor from an old Heterodyne AM radio.

It was about 1 foot per side, and had about 15 turns to resonate the BC

band. It was a very poor performer, but

gave me interest to keep on advancing.

The current set I have worked

up to is the 8’ Octagonal double tuned

X-tal set. I have included a Led light, a Digital spotter

radio, Ceramic insulated Silver Plated VC’s, and some nice calibrated

reduction

tuning knobs. These additions have made

for some pleasurable Dx-ing. It seems to

be a real performer, as I have logged over 85 stations at night, and DX

at 1400

miles. There are certain aspects that have drawn me

to loop sets, some include: precise station direction finding,

portable, deep

signal nulls, low noise signal source, neat looking, straight forward

construction, no dependence on external ground/antenna, very good

signal

gathering capability, and very high Q set potential.

I choose the Octagonal shape because it was

easily constructed, and gives near Round-Loop results. This

particular set is made out of 1x3x8 cheap lumber, has been stained and

sealed

to keep it looking fairly nice and to preserve longevity. Wood

was used because it was very easy to

work with, and was light weight.

I used a dado blade to make

the “Slots” in the wood frame material that allows it to be

assembled.

I also used the dado blade to produce the

slots on the ends of the frame that allows Styrene insulators to be

inserted. This would also be a good time for me to

mention a problem I have encountered with my current Loop. One of

the Horizontal spreaders now sags due

to the weight of the Variable Capacitor on it. It would be wise

in the future to support the

V.C. on the Tuned Loop from the interior of the Set as opposed to the

exterior.

Since the function of the main Tuned

Loop is to gather/reject signals it is necessary to build it in a

manner to

preserve all the “Q” possible. Keeping

in mind the afore mentioned, another aspect I tried to keep in mind on

this

Loop Radio is to minimize metals near the Loop. Metals in

proximity to coils have been shown

to distort reception patterns, so where ever fasteners were needed I

tried to

use less lossy materials. Fasteners

considered should include: brass,

stainless steel, or nylon.

|

Wire termination

insulator detail.

Wire termination

insulator detail.

The Styrene piece that is turned on edge is used to maintain wire

separation.

|

In past articles on

crystal

set design, I had seen some information about insulation materials and

their

benefits when used properly on components that are exposed to RF

energy. One of the materials mentioned was Styrene,

which usually is a white colored plastic and is very easy to work

with. Styrene is used in many ways, one of which is

for drain type plumbing. Genova products

is one such company that makes Styrene fittings, and should be easy to

locate

at local plumbing supply houses. Since

Styrene has been said to work well for RF insulators I thought I would

try my

hand in using it. As you can see in the

photos, the 18 gage wire never touches the wood directly, to help

minimize RF losses. The wire is suspended above the wood by the

Styrene insulators, and has yielded very noticeable results.

Usually the Styrene purchased from local

plumbing supply companies comes in fitting which are sometimes

curved. One way I found to straighten the rounded

pieces to make them into a more useful shape is to cut a certain amount

out of

the fitting, dunk it into boiling water and straighten it to the

desired

shape. The Styrene needs to be heated

by the boiling water a few minutes, and then can be easily

formed. I made a flat Stainless Steel jig to flatten

the Styrene to make the flat pieces seen in the photos behind the

Tuned-Loop

knob. My jig is two pieces of Stainless

Steel about 5”x 5” w/ small holes in the corners to facilitate screws

for tightening

the two halves together. I place the

Styrene to be flattened in the jig, insert screws w/ nuts into the four

holes,

place it in boiling water, and every couple minutes pull it out of the

water to

tighten the screws to flatten the Styrene.

This may not be the best or easiest way of making flattened pieces, but

it has worked well for me.

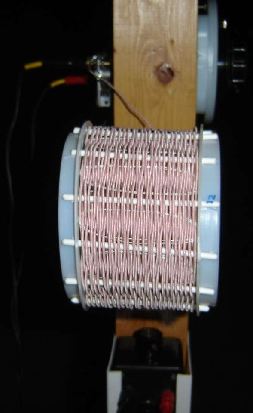

The wire I have chosen for

this particular tuned Loop was 18 Gage solid enamel

coated wire. I choose this particular

wire because it was the largest diameter solid wire I had

available.

I actually ended up reclaiming it from a

large power transformer! The next time I

create a new monster Loop, I will seriously be

considering high count Litz. There has

been much speculation that high count Litz wire may yield better

results on a

loop-type set as opposed to a standard Antenna/Ground type set. I

just haven’t saved up enough money yet to

give it a spin, but with any luck I will eventually. After

perusing Ben Tongue’s web pages I

decided to attempt a Contra-wound winding scheme on the main tuned

Loop,

and have noticed good results. Information on the Contra-Wound

winding

scheme can be found at www.BenTongue.com.

I also tried to maintain approx. Ľ inch spacing between adjacent

turns, in

order to minimize stray capacitance. The

wire ends also terminate into the Styrene insulators mentioned above,

but other

insulating materials may be used with good results. It is

also necessary to get the turns as tight as possible to restrict

movement, as

slightest movement of the wires can cause frequency variation or other

undesirable results.

I

choose to use a double tuned configuration to reduce direct loading on

the main

loop, which can increase selectivity and sensitivity. When using

a double tuned circuit one can

distance the two coils to reduce coupling, although other electrical

configurations could yield similar results.

The “Hobbydyne” type circuit is one I have in mind that could be

interesting to try when directly connected to the main tuned

loop. I haven’t tried it yet, but probably will

soon. I have often wondered if it is

better to reduce the coupling by physical coil separation, that way the

receiving

pattern is not distorted by the extra components it would take to

electrically

reduce coupling. Only time, and

experimentation will tell.

I currently use RCA Sound Powered phones

with a UTC-015/Bogen STM Impedance

matching circuit w/ a “Benny”. The two

diodes I have had excellent luck with are (1)1N770P10, and (2) HP

5082-2835’s

in parallel. Those have given me the

best weak level sensitivity, but I haven’t tried all that there is to

try. I am still learning, and it seems as my set

progresses with better VC’s and wire etc. I also find that the best

diode

changes from time to time.

I have attempted to give a general synopsis

of my Loop set. It is an ever-changing design, and gets

better all of the time. Much of this

information was learned on the Rap & Tap, and spending time on the

many

great websites doing research. I need to

give much credit to all the helpful guys on the Rap, they are

great! Hopefully this will inspire some to

reevaluate Loop performance, and possibly

build models with their own hints and wrinkles.

I know that I am always amazed at how well it

performs. Enjoy, and have fun!

Josh Young

|

|

Parts List

L1

Coil 3 turns (contra wound to L2) part of main loop

L2

Coil 3 turns (contra

wound to L1) part of main

loop

L3

Coil 420/46 Basket Weave Litz

C1

Variable Capacitor 15 - 400 pf

C2

Variable Capacitor 15 - 400 pf

D1

Diode 1N770P10

|

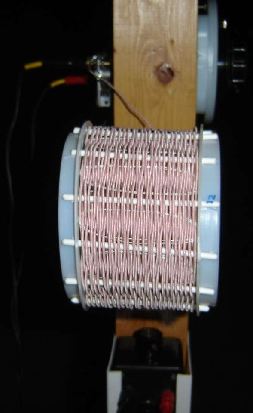

Detector Cap/ Basket Weave Coil assembly.

Detector Cap/ Basket Weave Coil assembly.

Vernier calibrated knobs are

used to make tuning nicer. Capacitor is protected inside the

Styrene drain spout adapter.

(left side photo)

Shows main Loop Tuning VC, and Main Loop Series/Parallel switch. (Right

side photo) Also shows the

1/4 “ shaft insulator as it goes into the Vernier dial to help

with any hand capacitance. |

| (left hand photo) The main Loop

Series/Parallel selector switch. (right hand photo) Basket Weave coil with form holder.

|

Photos of matching transformer

unit and holder (right side it is in it's holder)

Photos of matching transformer

unit and holder (right side it is in it's holder)

LED push button

LED push button

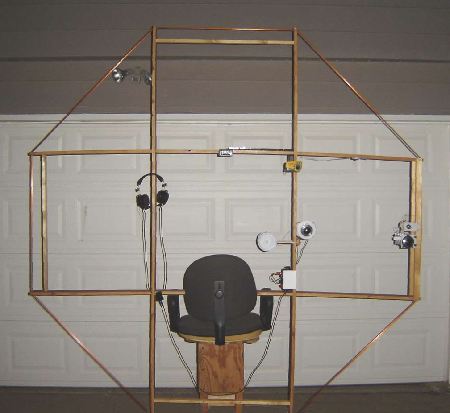

Photos of the original Loop Crystal Set

Sometimes it's fun to see the progression a a set

|