Stirling Walking Beam Engine

By Darryl Boyd

This is

a set of plans for a Stirling “hot” air engine. It incorporates a

“walking

beam” to transfer mechanical actions from one part of the engine to the

other. The walking beam is on the upper half of the engine and looks

like

an old weight scales. Walking beams were quite common on early steam

engine

of the 1800’s.

Caution

should be used when building this project. Hazards exist while building

any mechanical device and care must be taken during construction and

use.

We do not assume any liability for damage resulting in the use of the

enclosed

material.

Things to keep in mind while building and

attempting

to run for the first time.

Friction is this engine's

biggest

enemy. It hates anything being too tight. The bearings have to be

loose.

Sloppy is better than close tolerances.

If you are running the

shafts and

rods in the wood (I now don’t recommend this), it’s better to be loose

and oiled very well. Friction becomes more of an issue if no bearings

are

used. I recommend bearings made of brass tubing and sloppy on the

shafts.

The piston (1") should

fit loose

in the cylinder, not tight. This is not a situation where the piston

needs

to be tight like in an internal combustion engine. It is better to

loose

some pressure and vacuum that to create too much friction. If it is

loose,

oil it well (see oiling below) before running. This will help seal the

piston without causing too much friction. The lighter the piston, the

better

also. I make my pistons from 1" alum. rod drilled out in the back. This

will slide into 1" copper pipe very nice. I have been told that brake

cylinder

pistons work very good.

Oiling and lube. You can

lube the

piston cylinder and the rods and moving parts with a very light oil

like

WD40 or 3 in 1 oil, but if you use 30 wt oil or something heavy, It

will

not run. I oil the power cyl. with WD40 and use 3 in 1 oil (sewing

machine

oil) on every thing else. Make sure you oil the rod that goes into the

displacer on the top.

Remember - friction is our mortal enemy.

These engines are very

fussy about

friction. That is, all the joints and moving part have to be "loose",

very

loose. If the parts fit too tight, it will not work. This is the reason

most of the engines won’t work right off. Make it loose (but not

sloppy).

Oil the heck out of all

the joint

and the inside of the power piston cylinder and the rod going into the

displacer with something like WD40 or a very light oil.

Displacer Cylinder

We will begin with the main section of the engine

or “displacer cylinder”. It is made of a spray paint can. There are

generally

two sizes of spray paint cans. You will be looking for the larger size

measuring 7 ¾” high X 2 5/8” diameter at the base. This is where

some care must be observed. With the spray can completely empty,

remove the top with a can opener, but leave the top bead on the can.

You

can see why it is important to have the can empty. If you don’t empty

the

can, you will find paint and propellant coming out everywhere. This

could

be very dangerous. See Figure No.1

Power Piston Cylinder

Next

is the piston cylinder. This is made from a piece of 1” ID seamless

tubing.

Cut a 3 ½” long piece. Cope one end with a round file to pick up

the diameter of outside of the displacer cylinder. See Figure No.

2

Main Engine Assembly

Next we will build the main engine assembly. The

main engine assembly is made up of the displacer cylinder and the

piston

cylinder. At 3 7/8” down from the top of the displacer cylinder, braze

or silver solder or lead solder the piston cylinder on. Try to keep the

piston cylinder 90 degrees to the displacer cylinder. After this is

done,

drill a 3/8” hole through the displacer cylinder down through the

piston

cylinder. This will make a port for the air that is expanding during

heating

to push the piston forward, and when cooled, pull the piston back. This

is a double action piston.

Top Assembly

Next we will make the top assembly for the displacer

cylinder now part of the main engine assembly. Refer to Figure No. 3.

Drill

a 1/8” hole through the middle of a 3/8” x 1 ½” brass bolt. This

is best done with a lath, but if you are very careful, you can use a

drill

press. Doing it with a hand drill motor is very difficult. Care must be

taken to get it straight down the middle. Slightly counter sink both

ends

of the bolt with a counter sink or a larger drill bit. This counter

sink

allows for the rod to fit in much easier at a later time, and allows

for

oiling during running.

Now you must make two disks from the lids of old tin cans. One

must

be 2 5/8” plus in diameter and the other 2 ½” in diameter. The 2

½” diameter disk must fit inside the top bead of the displacer

cylinder.

At the center point of each disk, you must drill a 3/8” hole. Be

careful

when drilling the lids that they don’t spin on you and cut your

fingers.

Now to assemble the top of the displacer cylinder or top

assembly, place

the 2 ½” diameter disk on the brass bolt, followed by a 3/8”

washer,

then the 2 5/8” disk, followed by a 3/8” nut. Tighten up just snug. See

Figure No. 3.

Set these assemblies to the side for now.

Displacer Piston

The next item to make is the displacer piston. The

displacer piston goes inside the heat transfer cylinder. Using a small

tomato sauce can 3 3/8” tall by 2 1/8” in diameter with the sauce still

in it, drill a 1/8” hole in the center of the top and bottom lid. You

can

remove the tomato sauce from inside by blowing into one side and

letting

the sauce come out the other hole (not a pretty site!). Rinse with

water

and try to get as much out as possible. When dry, push a brass 1/8” rod

14” long through the hole on one side through the can and out the other

hole. The rod should stick out the bottom side about 1/16” or so. This

rod should have a "hook" on the end just in case you over heat the

engine. This will keep the displacer from falling off in that event.

Solder

this rod on at the top and bottom. See Figure No. 4

Back to the Main Engine Assemblies

Now take the displacer piston and insert it into

the 1/8” hole in the middle of the brass bolt on the top assembly. The

rod is inserted into the side with the smaller disk (2 ½”). This

assembly is placed displacer piston end first into the displacer

cylinder

and soldered or brazed onto the top of the displacer cylinder. See

Figure

Water Tank

The water tank is a 1 quart paint can. In the bottom

cut a 2 /12” plus hole. Slide this over the top of the main engine

assembly.

Solder the tank on making sure it is water tight when done. See Figure

No. 6. Water Tank is almost the same as the Fire Box in Figure No. 7

except

it does not have the 1/4” to 3/8” holes for venting and the hole in the

bottom is only 2 ½” plus.

Fire Box

The fire box is also made from a 1 quart paint can.

Cut a 2 5/8” hole in the bottom and drill 1/4” to 3/8” holes in side

around

the bottom end. Slide this on the bottom of the main engine assembly.

It

is held up in place with wires placed in the holes and taken up the

side

of the main engine assembly and bent over the top lip of the water

tank.

See Figure No. 6

Power Piston

The power piston goes into the piston cylinder on the main

engine assembly.

It is made up of a 1” piston from an automotive brake cylinder. You can

get this from any auto parts store in a rebuild kit or from an auto

wrecker.

Drill a 1/8” hole in the side about half way down. The connecting rod

is

a 1/8” x 12” + or - brass rod. I rolled the brass rod around a small

needle

nose pliers and made a closed loop on the end. I worked it down till it

made a good fit. All the joints on this engine wants to be very loose.

This engine hates friction and hates to be "tight". Keep it loose.

Another

way is to smash down the rod if you like and drill it out, just keep it

loose.We will put a loop in it later. See Figure No. 8.

Figure 8

Wrist pin.

After drilling the hole in the side of the piston

(1/8" for 1/8" rod) take a piece of 1/8" rod and slide it through the

piston.

cut it off just short of the outside of the piston. The wrist pin just

sits in the piston and can't come out because of the side walls of the

cylinder. Figure 8b

Stirling Walking Beam Engine

A) Main engine assembly support. Wood 2 ½” W x 1

¾” D

x 8” H with hole drilled in 1 ¾” side to accommodate

piston

cylinder OD at 7 3/16” up.

B) Walking beam support. Wood ¾” W x 1 ½” D x

17” H with

pivot hole at 16 ¾” from bottom.

C) Fly wheel. Wood 7 ½” diameter x ¼” thick

with hole

in center and one at 1 1/8” from center.

D) Walking beam. Wood ¾” H x ¼” D x 13” W with

holes as

noted in Figure No. 10

E) Base. Wood 12” x 22” ¾”. Base can be made smaller

if desired.

F) Fly wheel to walking beam rod. Brass 1/8” round rod x 9

5/8” center

to center. I make my rod slightly larger and place a kink in the middle

to measure 9 5/8” center to center. This allows me to fine tune the

timing

of the engine by adding or removing some of that kink.

G) Piston rod. Brass 1/8” round rod. Length is determined by rotating

point “J” to the three o’clock position and placing the piston in the

cylinder

where it is flush with the end of the cylinder. The rod should be able

to reach to point ”J”.

H) Fly wheel support. 1 ¾” W x 3” D x 8” H with hole

at 7 ¼”

up.

I) No “I” on drawing.

J) Crank point on fly wheel 1 1/8” from center of flywheel

“C”.

K) Connecting pin. Brass 1/8” round rod 1 ¼” center

to center

shaped as noted on Figure No. 10

Special Notes:

1) REMEMBER…..While assembly you make things too tight, it won’t run.

Without

the piston installed and the rod from the piston to the flywheel

removed,

and after oiling up, the entire walking beam and crank and displacer

should

rotate and move very freely. If you can’t get the flywheel to turn

around

3 to 5 times freely after spinning the flywheel lightly with your hand

(like a roulette wheel), then it is too tight.

2) Distance between A and B is 15/16”

3) Distance between A and H is 5”

4) The face of C and D and the centerline of the piston

cylinder and

the main engine assembly are all on the same plane.

5) Crank Point J is made from a 10-32 machine

screw.

6) The pivot point on the walking beam is made with a 10-32

machine

screw or can be screwed into B with a wood screw, but hole in B must

have

clearance to move freely.

7) You can make this engine too tight. It runs best when

there is a

bit of “slop” in all the moving parts except the piston which should

not

be too tight either.

8) Where moving bolts or shafts make pivot points or

bearings in wood,

you can “line” the wood with brass tubing from hobby shops or hardware

stores. This will create a “bearing” so the machine screws are running

on brass and not wood. This is highly recommended.

9) Put water in upper cooling tank and use sterno for fuel.

Other things

can be used as fuel also. Don’t make it too hot, but it will not run if

it is too cold.

10) Keep all moving joints well oiled.

11) Fly wheel rotates in a counter clockwise direction.

12) Oil all joints before operating.

13) Start heat and rotate fly wheel where the “crank point”

is down.

As the engine heats up you will see the piston try to push out of the

cyl.

slightly. This will rotate the fly wheel just a little. This happens as

the air in the main cyl. heats up and expands. This will be an

indication

the engine is almost ready to start.

14) The air in the bottom of the main engine assembly heats

up when

the displacer piston is in the up position. The air expands and

pushes

the piston out rotating the flywheel and moving the walking beam in the

opposite direction. That lowers the displacer piston down, pushing the

heated air up into the top of the main engine assembly. The air now

cools

rapidly with the aid of the water tank. The air condenses and pulls the

piston back into the piston cylinder, which rotates the flywheel and

moves

the walking beam in the opposite position, which raises the displacer

piston

to the upper position forcing the cool air down to the bottom where it

is heated again and the cycle starts all over.

15) As the water in the top heats up the engine will run

slower because

there is less of a difference between the hot side and the cold side.

This

engine will run at different speeds depending on the difference between

temps of the water in the upper tank and the heat source.

Possible Alternatives

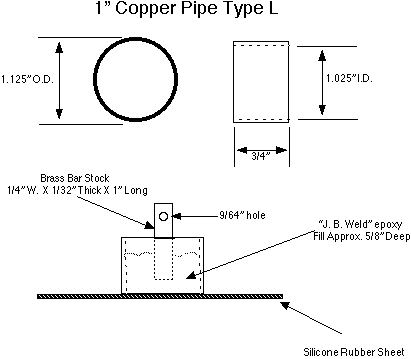

No.1

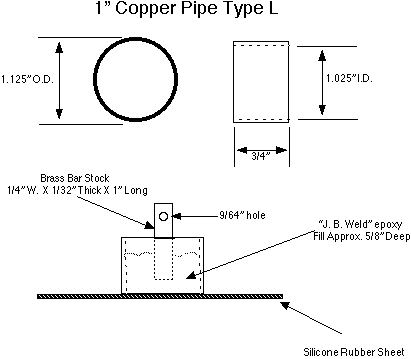

The Haigh piston

This is a possible alternative to a

lathe

turned piston or a brake piston.

The following is an email sent to

me by Dan

Thought I'd pass on a hint

for those folks

who don't have a lathe, but want to make pistons to fit 1" Type M

copper

pipe. Since both Type M (1.055" I.D.) and Type L

(1.025" I.D.) are readily

available in most

areas, here's what I did:

I cut a 3/4" long piece of

Type L using a tubing

cutter and carefully deburred the inside of both ends (a jackknife

works

fine). I then coated the inside with a thin

coating of grease and set it on

a sheet of

silicone rubber gasket material. The 3/4" cylinder was then

filled

to 1/8" from the top with mixed, 2-part epoxy (I used a

product called "J-B Weld"

because it makes

a fairly thick mix that won't leak out and it's good to 600 degrees

F.).

I then suspended a short (about 1") piece of 1/4" X

1/32" brass bar stock (with a

9/64" hole for

the connecting rod) centered in the mix. A small alligator clip

works

fine for holding the bar stock in place while the epoxy

cures.

I let the epoxy cure

overnight, then pressed

out the finished piston with a bearing press. If a bearing press

or strong drill press isn't available, the piston can be removed

by carefully cutting through the

copper pipe

section with a hacksaw and prying it apart.

The resulting lightweight

piston will need

a very minor amount of sanding on the leading edge and then will fit

beautifully

into Type M copper pipe. I know the above

directions are a bit confusing,

so I'm attaching

a sketch of what I mean.

Best regards,

Dan Haigh

|

No.2

Oiling Tip/Change

Power Piston Oiling. Allows oiling

during

running.

© Darryl Boyd

April 2001, January 2003, Feb 2003, March 2004,

August 2005

|